In today’s fast-paced manufacturing landscape, the importance of high-quality injection mould tooling cannot be overstated. Selecting a leading automotive tooling manufacturer to produce high precision injection mould tooling not only ensures superior craftsmanship but also reflects positively on the quality of the finished moulded components. In this blog, we will delve into the reasons why opting for an automotive tooling specialist for diverse industries, including medical, aerospace, packaging, and health and safety, is a game-changing decision.

Exemplary Craftsmanship:

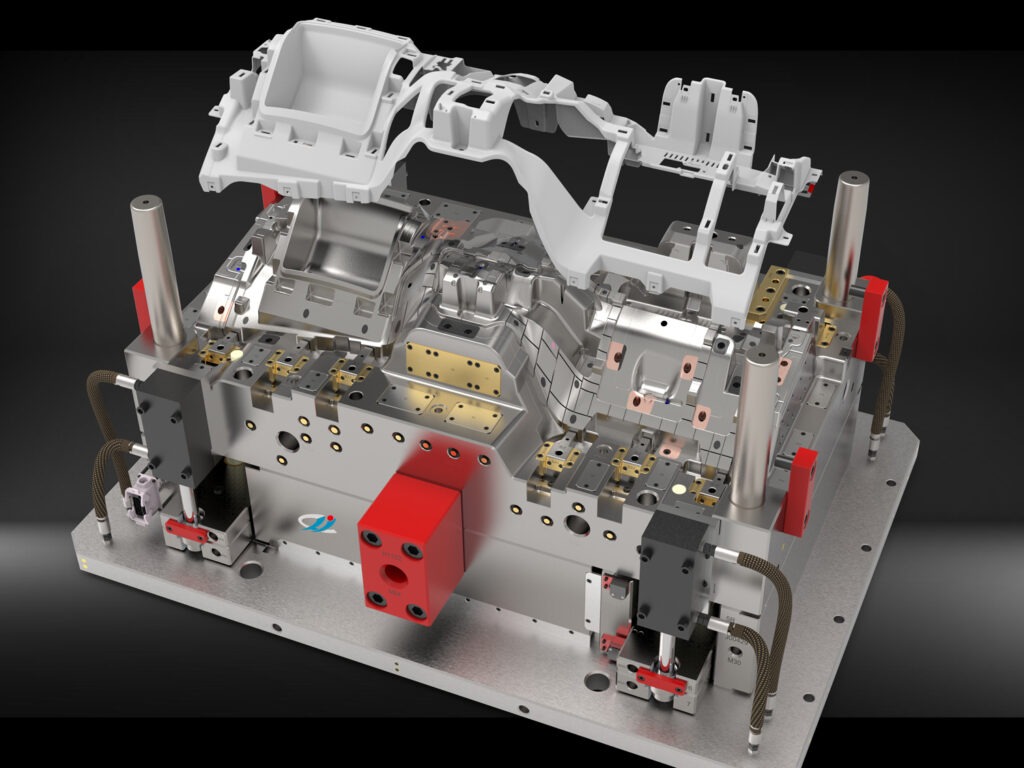

Automotive tooling manufacturers are renowned for their precision engineering and attention to detail. With years of experience in producing complex and intricate automotive parts, these manufacturers bring a level of craftsmanship that is unparalleled in the industry. This expertise translates into high precision injection mould tooling, guaranteeing flawless performance and the highest quality moulded components.

Cutting-Edge Technology:

Leading automotive tooling manufacturers invest in state-of-the-art technology and advanced machinery. Their commitment to innovation allows them to stay at the forefront of manufacturing processes, delivering tooling solutions that adhere to the latest industry standards. The integration of cutting-edge technology ensures precise and consistent moulding results across various industries.

Rigorous Quality Control:

Quality is the cornerstone of automotive tooling manufacturers. They adhere to stringent quality control protocols throughout the tooling process, from design to final production. This unwavering commitment to excellence ensures that the moulded components meet the exact specifications and requirements of each industry, including medical, aerospace, packaging, and health and safety.

Material Expertise:

Automotive tooling manufacturers possess extensive material knowledge, a crucial aspect when dealing with diverse industries. Whether it’s medical-grade plastics, aerospace-grade composites, or food-safe materials for packaging, these manufacturers understand the unique properties and challenges associated with different materials. This expertise guarantees that the injection mould tooling is optimised for the specific application, resulting in top-tier moulded components.

Customisation and Adaptability:

Each industry demands unique tooling solutions due to varying design complexities and functional requirements. Automotive tooling manufacturers excel in creating customised tooling solutions tailored to the needs of different industries. Their adaptability to evolving demands ensures that the tooling can accommodate changes and advancements in the manufacturing process, delivering consistent, high-quality results.

In conclusion, selecting a leading automotive tooling manufacturer, such as HH Plastics Metal Co., Ltd, for high precision injection mould tooling is a strategic move that elevates the quality of moulded components across diverse industries. Their exemplary craftsmanship, cutting-edge technology, rigorous quality control, material expertise, and adaptability make them the preferred choice for industries like medical, aerospace, packaging, and health and safety. By choosing such a manufacturer, businesses can rest assured that their injection mould tooling is crafted with precision, resulting in superior finished moulded components that meet the highest standards of quality and performance. Embrace the expertise of automotive tooling specialists and unlock the potential for excellence in your manufacturing processes.