End Of Arm Tooling

End of Arm Tooling

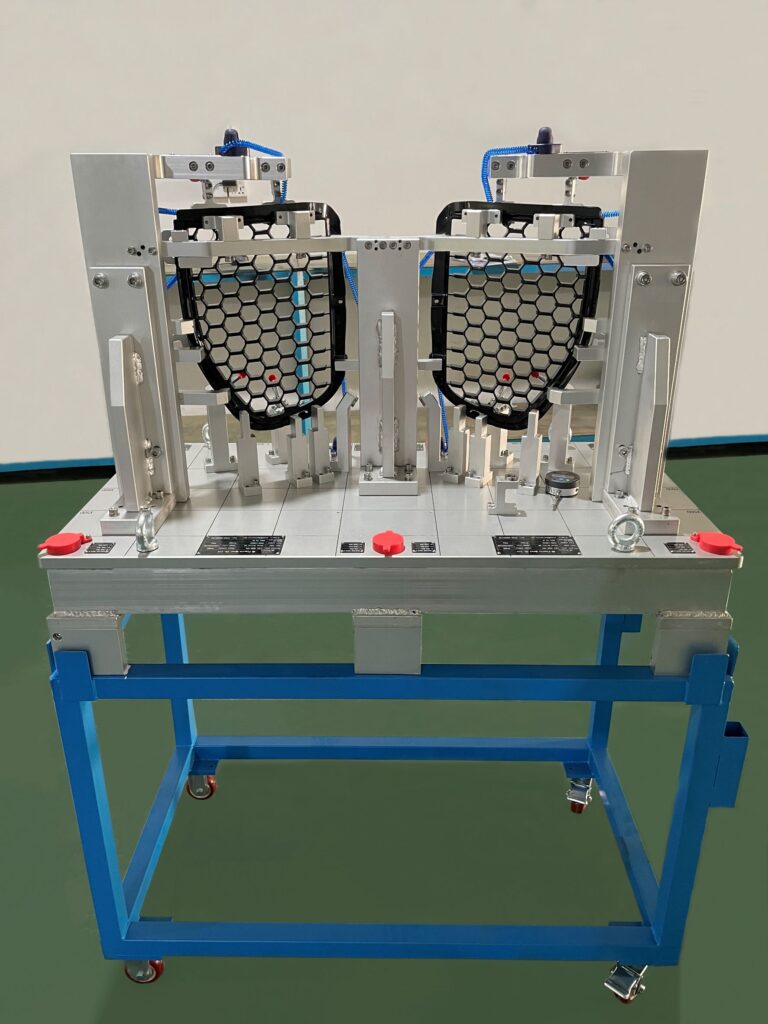

For Injection Moulding Robotics

Here at HH Plastics, we go the extra mile and help our customers with the specific end of arm tooling required for their bespoke plastic injection moulded parts. The advantage we have, is that we have all of the dimensional data from the tooling manufacture to replicate precise dimensions required for the most efficient end of arm tooling. All of our end of arm tooling is compatible with the majority of the worlds largest robotics manufacturers, therefore it is simple to install and programme. We also offer a full in house design service, and ensure that all end of arm tooling is tested thoroughly before dispatch, to ensure no issues when it arrives at your factory.

Our mission is to provide high-quality tooling with meticulous attention to detail.

The manufacture of the tooling for your project is only one part of the very complex process of producing the highest specification plastic moulded component. Removing these moulded parts via robotics, and our very best end of arm tooling will be the next process. Ensuring that your parts adhere to exact tolerances permitted is the vital stage of the quality process, therefore here at HH Plastics, we design, develop and manufacture the jigs and fixtures required for measuring the vital areas on your moulded components.

By using the HH Plastics jigs and fixtures, you can maximise the operational efficiency of your quality department, by reducing time spent on the measuring, fit and function side of your business. You will have full traceability for your ISO certification and can ensure that the jigs and fixtures are always kept within specification but testing with the master samples. Any re-calibration can be quickly and accurately completed.

We carry our rigorous testing on all Jigs and Fixture prior to shipping, therefore you will have full peace of mind that your manufacturing process will be seamless, from installing the tooling into your moulding machine, picking parts via your robotic heads, though to tolerance checking on your jigs and fixtures.