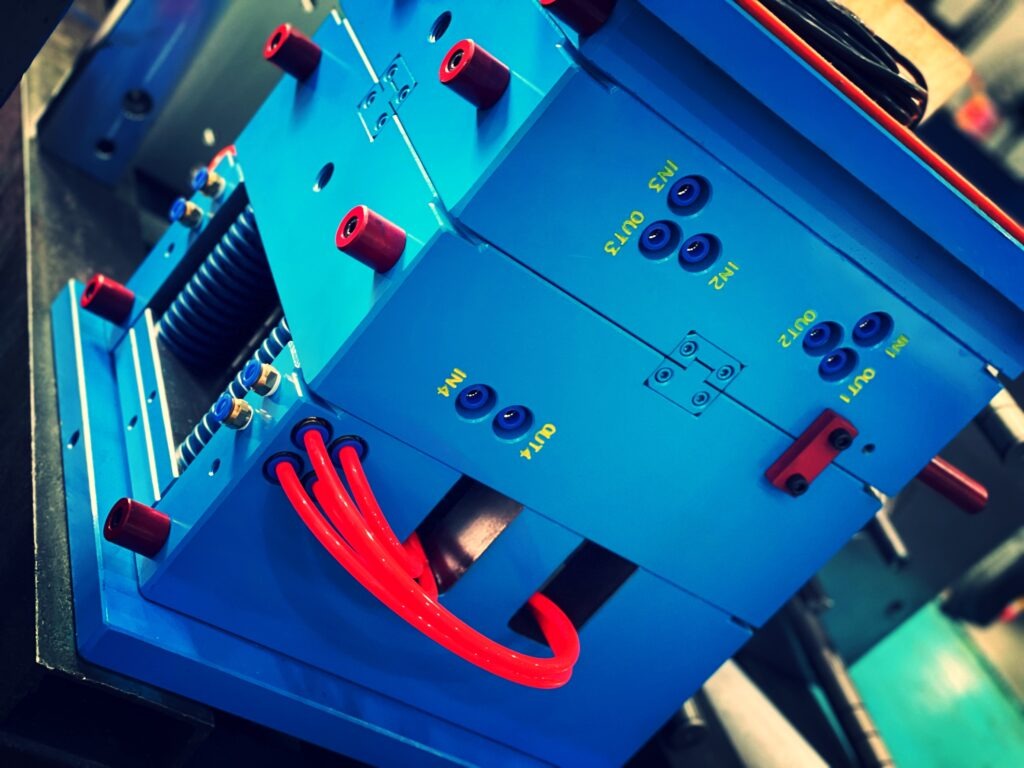

Two Plate Injection Mould

World-Leading Precision With Two Plate Injection Mould Tools

At HH Plastics, we know the importance of delivering high-quality, precision-engineered products. A cornerstone of our success is our expertise in producing injection mould tools, with a particular focus on two plate injection moulds.

This method, which has long been trusted in industries ranging from automotive to consumer goods, offers several distinct advantages, making it the perfect choice for a wide range of applications.

By using two plate injection moulds, we can provide our clients with exceptional manufacturing standards that are optimised for efficiency, cost-effectiveness, and design flexibility!

What Is A Two Plate Injection Mould?

A two plate injection mould is a type of mould commonly used in the injection moulding process to create plastic parts. It is comprised of two primary components: the “A” plate (the cavity plate) and the “B” plate (the core plate).

These two plates work in tandem to create the cavity into which the molten plastic is injected. As the mould closes, the two plates meet, forming the shape of the product that will be created. After the injection process, the plates open again, and the part is ejected from the mould.

The simplicity of this design makes two plate injection moulds an ideal solution for many applications, offering speed, precision, and efficiency at competitive prices. Whether you’re developing complex consumer products or automotive components, the versatility and reliability of two plate injection moulding can deliver the results you need.

How Two Plate Injection Moulds Work

At HH Plastics, our two plate injection moulding process involves several key steps to ensure quality and precision:

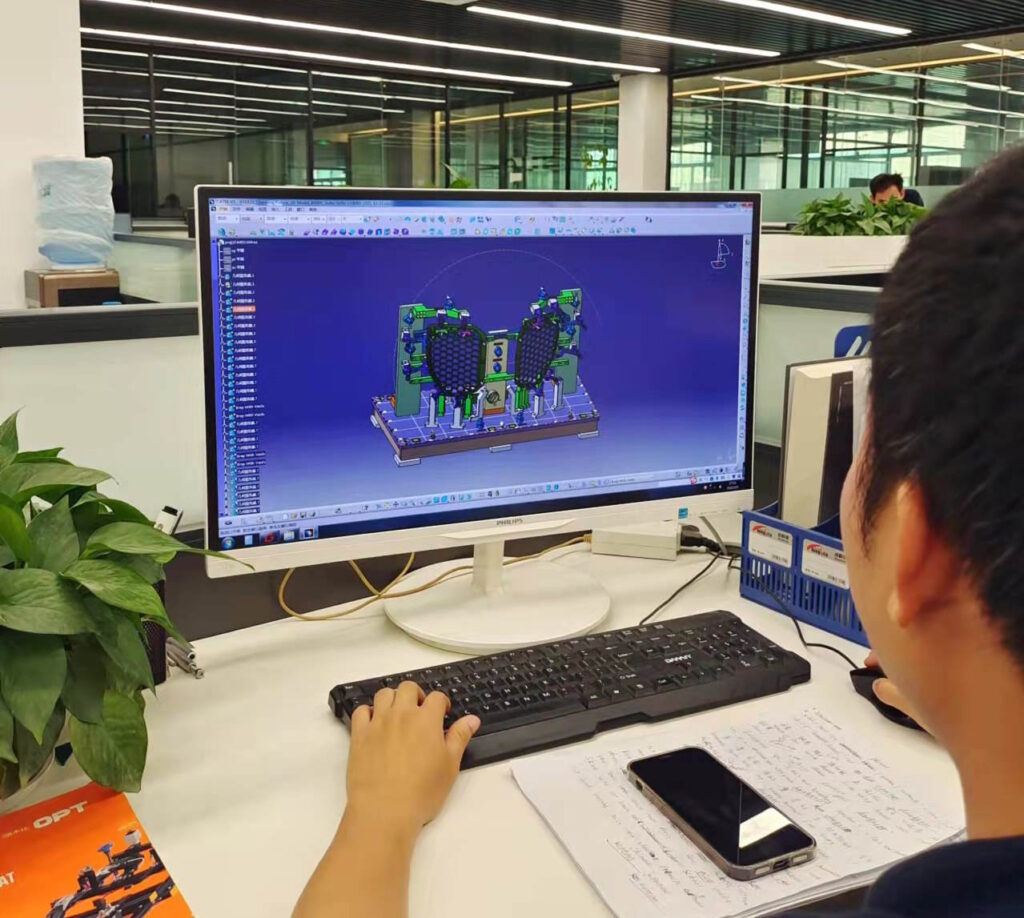

1) Mould Design: The process begins with designing the two plate mould itself. Our experienced team of engineers collaborates closely with clients to understand the specific requirements of the product.

This includes considerations such as part geometry, material selection, and the number of cavities needed. Using cutting-edge CAD software, we create a digital model of the mould, ensuring that every detail is meticulously planned.

2) Mould Fabrication: Once the design is finalised, we move to the fabrication phase. The two plates (A and B) are machined from high-quality steel or other materials, depending on the intended application.

The plates are carefully crafted to precise tolerances to ensure a perfect fit, and the cavity and core are shaped to match the desired product specifications.

3) Injection Moulding Process: With the mould in place, the next step is the injection process. Molten plastic is injected into the cavity through a nozzle. The mould is then cooled, allowing the plastic to solidify. Once the part is fully formed, the mould plates open, and the finished product is ejected.

In some cases, the product may require post-processing or trimming to achieve the desired finish.

4) Quality Control: At HH Plastics, quality is of paramount importance. Our dedicated team conducts rigorous quality checks at every stage of the process, ensuring that each part produced meets the highest standards.

We use advanced testing equipment to verify critical dimensions, mechanical properties, and material consistency, ensuring that our clients receive parts that are both functional and durable.

Our mission is to provide high-quality tooling with meticulous attention to detail.

The Benefits Of Two Plate Injection Mould Tools

Two plate injection moulds offer numerous advantages for a wide range of industries. Here are just a few of the benefits our clients experience when using this type of mould:

Cost-Effective Manufacturing: One of the most significant advantages of two plate injection moulds is their cost-effectiveness. The design and fabrication of these moulds are less complex than three-plate moulds, which translates to lower production costs.

This means for businesses looking to reduce overhead expenses, two plate moulds provide an affordable option for high-quality manufacturing.

Faster Production Times: The simplicity of the two plate design also leads to faster cycle times. With fewer moving parts and a more straightforward operation, two plate moulds can produce parts more quickly than more complex moulding systems.

This means shorter lead times, faster time-to-market, and improved overall efficiency for our clients.

High Precision And Consistency: Despite the simpler design, two plate moulds are capable of achieving extremely high levels of precision. At HH Plastics, we employ advanced manufacturing techniques and quality control procedures to ensure that each part meets strict dimensional tolerances.

This results in products that are both reliable and consistent, helping our clients to meet their performance requirements.

Design Flexibility: Two plate injection moulds are ideal for producing parts with relatively simple geometries. Whether you’re manufacturing a small batch of custom products or a high-volume run, two plate moulds offer the flexibility to accommodate a wide range of design specifications.

Reduced Maintenance Costs: Due to the fewer moving components in a two plate mould, maintenance is typically less frequent and less costly compared to three-plate moulds. This makes it an attractive option for businesses looking to keep operational costs down while maintaining high manufacturing standards.

Improved Cycle Times And Efficiency: Because of the reduced complexity of the mould, cycle times are often faster with two plate moulds, leading to increased productivity.

With quicker turnarounds, businesses can ramp up production volumes to meet demand, reducing downtime and improving overall operational efficiency.

Versatility In Material Use: Two plate injection moulds can work with a wide variety of materials, including thermoplastics, elastomers, and certain thermosets. This versatility allows us to produce a broad spectrum of products, from medical devices and packaging to automotive components and consumer electronics.

While two plate moulds are an excellent solution for many applications, it’s important to understand when this method is the best choice. Two plate injection moulds are particularly well-suited for products with simple to moderate geometries that do not require the complexity of a three-plate mould.

They are ideal for:

- High-volume production runs

- Small to medium-sized parts

- Products with fewer undercuts or complex features

- Applications where cost-effectiveness and speed are key priorities

More complex designs with intricate features, multiple cavities, or more complicated ejection systems may benefit from the use of a three-plate mould. At HH Plastics, we offer expert advice and guidance to help you determine the most suitable moulding method for your project.

HH Plastics: Expertise You Can Rely On!

At HH Plastics, we pride ourselves on our expertise in producing high-quality two plate injection mould tools.

Our team of engineers and technicians work closely with clients to ensure that every project is executed to the highest standards, from the initial design phase through to production and final inspection. With decades of experience in the injection moulding industry, we have the knowledge and skills to help you bring your products to life.

We understand that every project is unique, and we are committed to offering tailored solutions that meet your specific requirements. Whether you are a startup looking to create your first product or an established business needing to scale up production, HH Plastics is your trusted partner in injection moulding.

By choosing HH Plastics, you are choosing a company that is dedicated to providing exceptional value, quality, and service. Our two plate injection moulds are designed with precision and efficiency in mind, ensuring that your products are produced to the highest standards, on time, and within budget.

Two plate injection moulds are an excellent choice for a wide variety of applications, and at HH Plastics, we have the expertise and experience to deliver exceptional results. From reducing production costs to ensuring consistent quality and faster cycle times, two plate moulds offer numerous benefits for businesses looking to manufacture high-quality plastic products.

If you’re looking for a reliable, cost-effective solution for your next project, HH Plastics is here to help. Get in touch with us today to discuss your requirements and find out how our two plate injection moulding services can benefit your business.