What We Do

Welcome to

HH Plastic Metal Co., Ltd

Our commitment to excellence and innovation sets us apart in the world of Plastic Injection Mould Tooling, Tool Design, End of Arm Tooling, Gauges and Checking Fixtures. We pride ourselves on offering a comprehensive range of services tailored to meet the unique needs of our customers. Our goal is to provide high-quality tooling that enhances your manufacturing processes and drives your success.

Here’s what we offer:

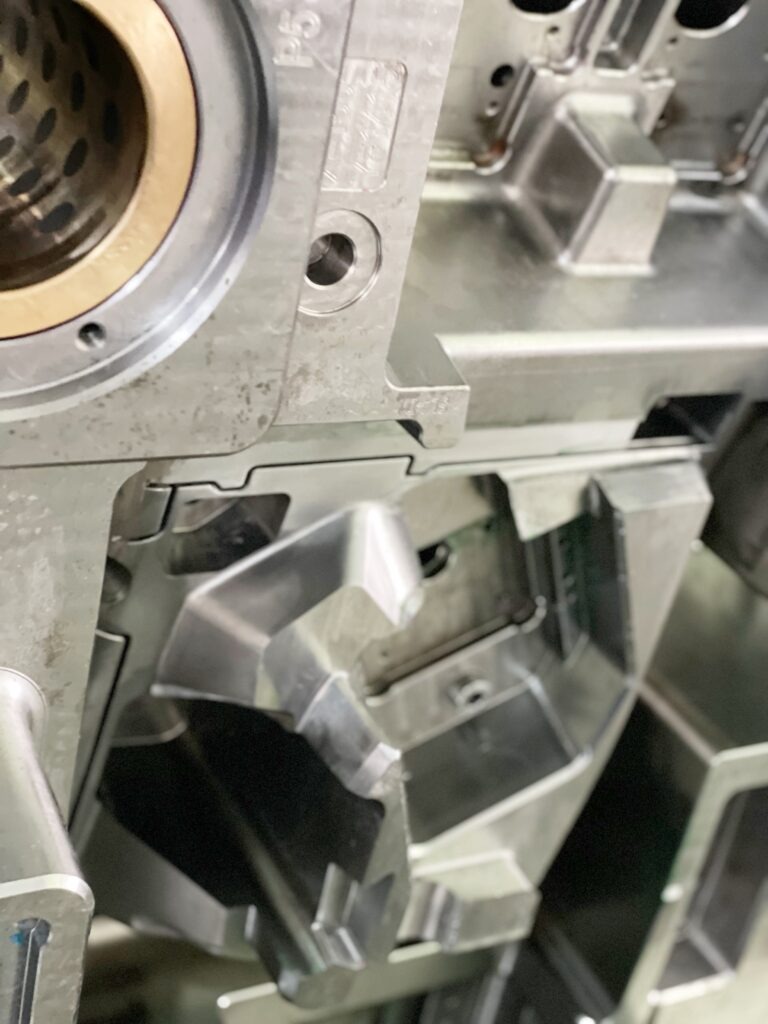

Comprehensive Plastic Injection Mould Design – At HH Plastic Metal Co., Ltd, we specialise in creating precision-engineered plastic injection mould designs that meet the highest standards of quality. Our experienced team of over 40 designers and engineers work closely with you to understand your specific requirements, ensuring that every design is optimised for efficiency, durability, and performance.

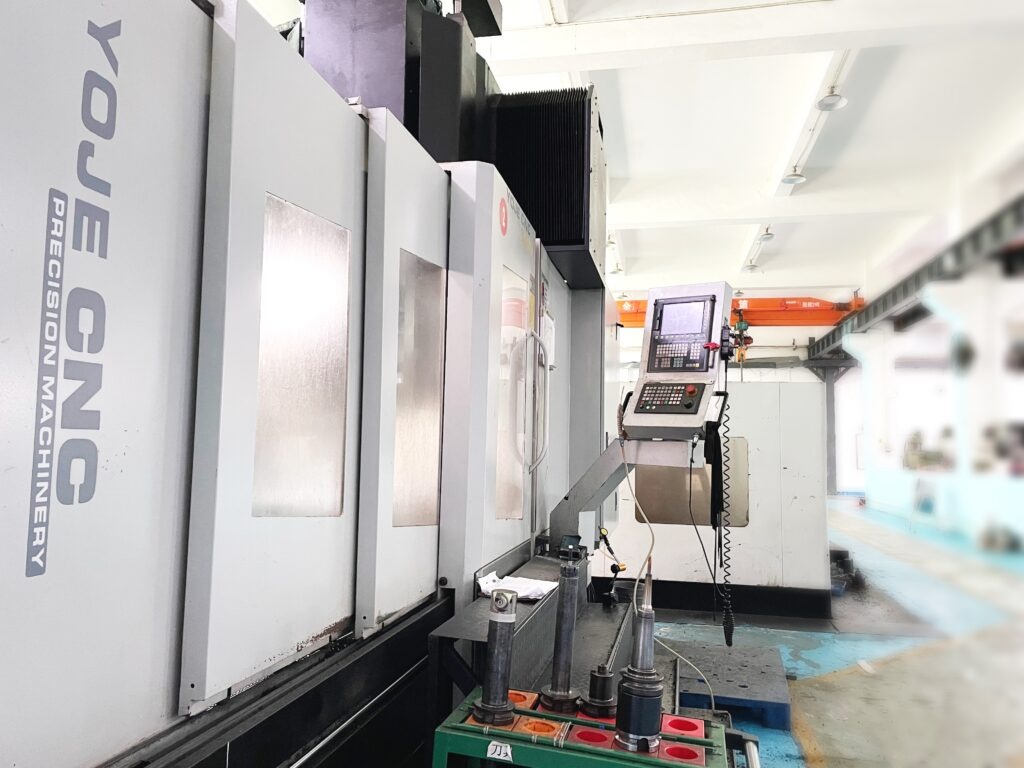

Advanced Tooling Solutions – Our state-of-the-art tooling solutions are crafted to support a wide range of applications, delivering unmatched accuracy and reliability. We use the latest technology and materials to produce tools that are robust, long-lasting, and capable of meeting the most demanding production needs.

Full Turnkey Solutions – We understand that our customers require a seamless and hassle-free experience. That’s why we offer full turnkey solutions that cover every aspect of the plastic injection mould tooling process. From initial concept and design through to manufacturing, assembly, and delivery, we manage every step to ensure a streamlined process and superior end product.

"We envision a future where our world-class Plastic Injection Mould Tooling, Tool Design, End of Arm Tooling, Gauges and Checking Fixtures set the industry standard for quality and innovation."

- Concept Development: Collaborating with you to transform your ideas into practical, innovative designs.

- Prototyping: Developing initial designs to validate concepts and refine functionality.

- Tooling: Designing and manufacturing precision mould tools for high-quality production.

- End of Arm Tooling: Creating specialized components for automated machinery to enhance efficiency.

- Checking Fixtures: Providing custom fixtures to ensure accurate measurement and quality control.

- Assembly Fixtures: Designing and fabricating fixtures to streamline and support the assembly process.

- Gauges: Developing precise gauges for accurate measurement and quality assurance.

- Assembly and Finishing: Offering comprehensive assembly and finishing services to ensure your products are ready for market.

- Quality Control: Implementing rigorous quality control measures at every stage to guarantee the highest standards.

- Logistics and Delivery: Providing efficient logistics solutions to ensure the timely delivery of your products.

- Our solutions cover every stage of the process, ensuring you receive a fully integrated system that simplifies production and meets your exact specifications.

- Custom Solutions – Every project is unique, and we take pride in our ability to offer customized solutions that cater to your specific needs. Whether you require specialised materials, unique design features, or tailored production processes, we work closely with you to deliver exactly what you need.

- Exceptional Service and Support – At HH Plastic Metal Co., Ltd, we believe that exceptional service is key to our success. Our dedicated team is always available to provide support, answer questions, and ensure that your project runs smoothly from start to finish. We are committed to building strong, collaborative relationships with our customers based on trust, transparency, and mutual success.

- Industries We Serve – We are proud to serve a diverse range of industries, including automotive, electronics, consumer goods, medical devices, aerospace and more. Our extensive experience and versatile capabilities enable us to meet the unique demands of each sector, providing solutions that drive innovation and efficiency.

- Commitment to Sustainability – We are dedicated to sustainable practices and strive to minimize our environmental impact. Through the use of eco-friendly materials and efficient manufacturing processes, we are committed to contributing to a greener future.

High-quality, world-class injection mould tooling is crucial across these industries for several reasons:

- Precision and Accuracy: Ensures components meet exact specifications, critical for performance and safety.

- Durability and Longevity: High-quality tooling reduces wear and tear, ensuring longer tool life and consistent production quality.

- Efficiency and Cost-Effectiveness: Superior tooling minimizes defects and production downtime, leading to cost savings and higher productivity.

- Compliance and Standards: Industries with stringent regulatory requirements rely on high-quality tooling to meet compliance and quality assurance standards.

- Innovation and Competitiveness: Advanced tooling capabilities enable the production of innovative designs, helping companies stay competitive in their markets.

At HH Plastic Metal Co., Ltd, our expertise in injection mould tooling across various industries underscores our commitment to quality and innovation. Contact us to learn more about how our high-quality tooling solutions can meet the unique needs of your industry and help you achieve your manufacturing goals.