Plastic Molding Companies

We Provide World-Leading Plastic Molding Services

At HH Plastic Metal Co., we specialize in manufacturing custom plastic injection molding machine tooling for clients across various industries such as Consumer Electronics, Home Appliances, Automotive, Medical, and Electronics.

We are proud to supply our global client base with high-quality injection mold tooling, meticulously crafted by our team of engineers using the latest Computer-Aided Design (CAD) technology. Working closely with our Project Managers, our experienced CAD engineers create premium products, focusing on precision and meticulous attention to detail.

If you’re seeking quality tooling at cost-efficient prices, make sure you get in touch. With our global production approach, from our manufacturing base in Shenzhen, China, we have the ability to provide superior injection mold products and services to clients across the globe.

This has earned us a reputation as trusted providers of mold tooling solutions for a wide range of high-profile clients worldwide.

Our mission is to provide high-quality tooling with meticulous attention to detail.

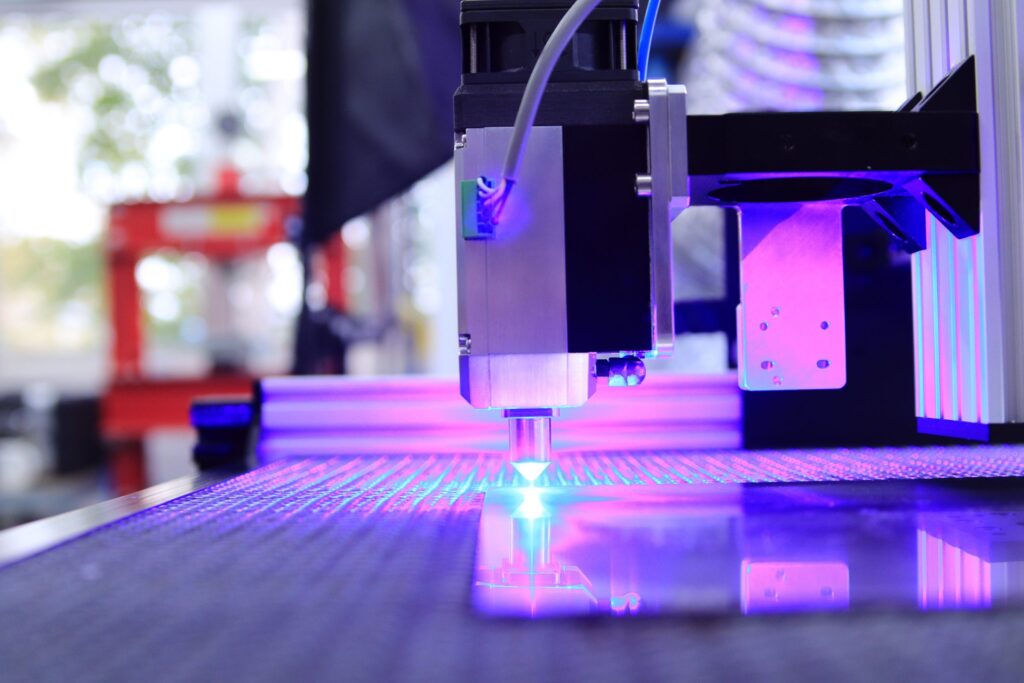

As leading plastic injection mold tool manufacturers for the automotive industry, we employ state-of-the-art techniques to create high-precision mold tools suitable for a wide range of plastics and polymers, including those used in high-performance engineering.

With our expertise in design and development, we can produce tools tailored to almost any specification.

Our CAD design team, consisting of 40 skilled professionals, possesses the necessary technology and skill set to develop tooling for both interior and exterior automotive features. From intricate small components to extra-large body parts and bumpers, we can meet your requirements.

We are honored to be trusted suppliers of Plastic Injection Mold Tooling to esteemed brands in the Automotive Industry. Our clientele includes renowned companies such as Bentley, Aston Martin, Peugeot, McLaren, and Jaguar Land Rover.

Injection molding technology plays a vital role in the creation of various devices found in homes and offices.

From minute details on phones and laptops to large electronic components like television screens, millions of these essential parts are produced daily. Each component requires meticulous care and precision to ensure it meets the exact specifications necessary for optimal functionality.

At HH Plastic Metal Co. Ltd., we are globally recognized manufacturers of bespoke tooling for the consumer electronics industry.

We supply Plastic Injection Mold Tooling to prestigious companies in this sector, ensuring the highest quality standards are met.

Due to the large volume of parts produced within the Home Appliances industry, it is imperative to have reliable and durable tooling.

At HH Plastic Metal Co. Ltd, we leverage our in-depth understanding of manufacturing processes to create quality tooling that meets world-leading OEM standards.

We pay meticulous attention to detail, produce high-quality products, and offer enhanced customer support to our esteemed household-name clients.

Environmental considerations are a crucial consideration when designing tooling for the Home Appliance market. We provide Mold Flow Analysis and Design for Manufacturability (DFM) services to minimize cycle time, reduce equipment wear and tear, and maximize production efficiency.

We understand the significance of using quality components and precise waterways for optimal internal temperature regulation, thereby reducing the likelihood of excessive scrap parts during long manufacturing runs.

Whether you require multi-cavity tooling, family tooling, or large single impression molding, our skilled team has the experience and expertise to deliver exceptional results consistently.

Our goal is to surpass our clients’ expectations by providing well-built tools and outstanding customer service that meet their high-performance criteria.

This core value has enabled us to foster long-term business relationships with our blue-chip customers.

At HH Plastic Metal Co., we understand that tooling for manufacturing industries must be capable of producing high volumes of products. That’s why all our mold tooling comes with a standard 500,000-shot tooling guarantee.

We stand behind this promise, prioritizing build quality and design standards throughout our engineering process. Our tools are designed for high cycle counts and crafted from the highest quality steel to ensure optimal results.

To ensure the suitability of the tool design, we conduct thorough Design for Manufacturability (DFM) and Mold Flow Analysis. Additionally, we offer the option to add specific textures to the finished tooling, enhancing the final molded product’s appearance.

Customer support and satisfaction are of utmost importance to us. Our professional design consultancy service is available to assist you in developing a manufacturing process that runs smoothly and efficiently, resulting in high-quality plastic injection molds that not only meet but exceed your production needs.

During the tooling design phase, we consider how the tooling will be utilized in practice, paying careful attention to these principles in every design. This meticulous approach allows us to deliver premium-quality products while minimizing waste and reducing expenses.

For All Your Plastic Molding Requirements, There Is No Better Option Than HH Plastic Metal Co.!