Plastic Injection Molding Factory

Our Plastic Injection Molding Factory Creates Top-Quality Injection Mold Tools For Businesses Around The World

At HH Plastic Metal Co. our plastic injection mold factory specializes in the design and manufacture of Plastic Injection Mold Tooling for esteemed clients across the globe. Our service caters to a wide range of industries, including Customer Electronics, Home Appliances, Automotive, Medical, and Electronics.

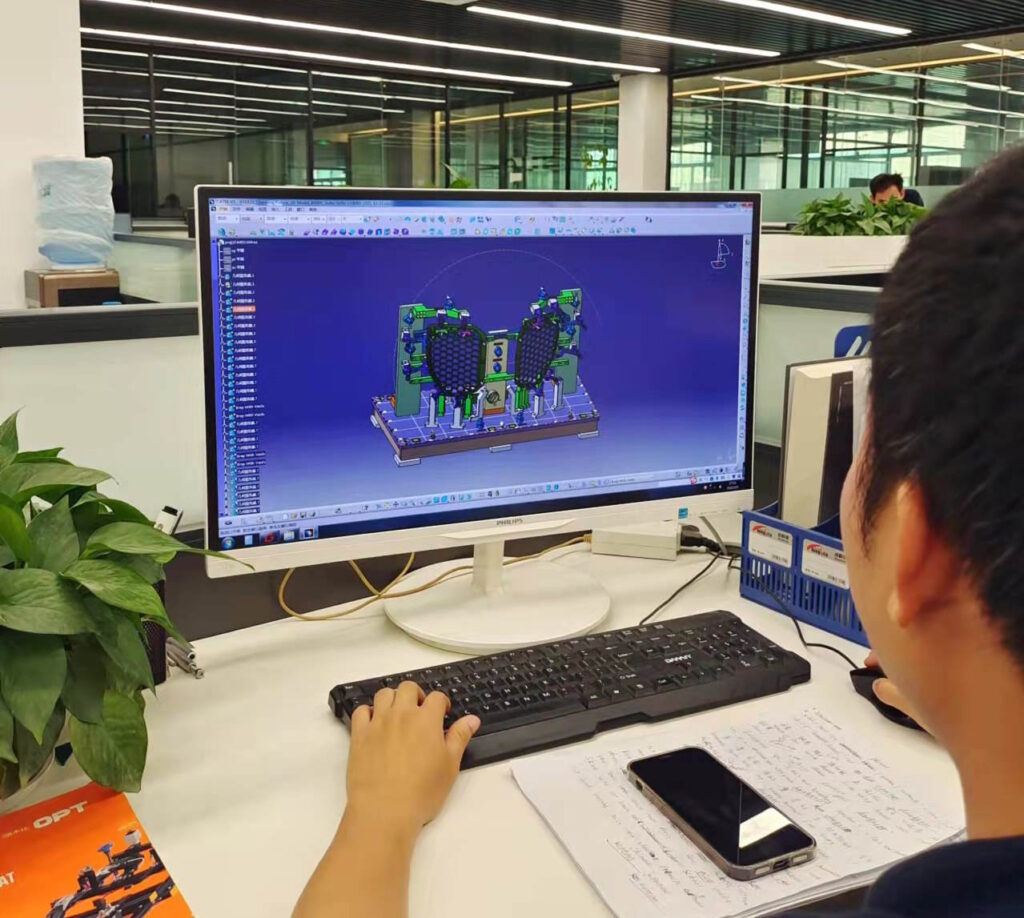

Our team of skilled engineers utilizes cutting-edge Computer-Aided Design (CAD) technology to meet the diverse needs of our clients. Collaborating closely with our Project Managers and clients, these CAD engineers produce bespoke Plastic Injection Mold Tooling that adheres to precise specifications while upholding unparalleled levels of precision, meticulous attention to detail, and stringent quality control.

We adopt a global approach to production, operating from our manufacturing base in Shenzhen and a UK-based management team. This approach allows us to deliver quality products and services at cost-efficient prices, earning us a reputation as a trusted supplier of Injection Mold Tooling for renowned global brands.

We take pride in our commitment to excellence and the lasting professional relationships we have cultivated as a result!

We recognize the vital role of stringent quality control as providers of custom Plastic Injection Mold Tooling services to our esteemed global clients.

In light of this understanding, our unwavering commitment lies in delivering nothing short of the highest standards of quality and meticulous attention to detail in every facet of our business. From initial design to final production, we prioritize excellence and customer satisfaction at every step of the process.

Our Injection Mold Tooling design service provides our valued clients with cutting-edge advancements in data transmission, modeling, digitized information, and reverse engineering.

Our team of expert CAD engineers uses state-of-the-art CAD technology and manufacturing processes to transform your designs into functional tooling products, all while upholding the utmost standards of quality.

To further enhance our clients’ experience, we offer access to Finite Element Analysis and Moldflow Analysis images during the design stage, reducing the potential need for expensive and time-consuming modifications in the future.

By avoiding such setbacks, we enable our clients to optimize their time and financial resources, resulting in an efficient and cost-effective design process.

Our CNC Milling Department operates seamlessly through a direct network link that connects our designers to the shop floor computers. It is here that our highly skilled team of machine operators, equipped with their expertise, develop their own machining programs.

This interconnected structure allows us to facilitate effective data transfer and seamless communication across all teams. By supporting collaboration, we can provide a cohesive service that maximizes efficiency while minimizing errors.

Our CNC Milling Machines are renowned for their exceptional efficiency, delivering precise mold tooling at a rapid pace. To achieve high levels of precision, our skilled operators harness the power of state-of-the-art software and controls. This ensures that every machined tool meets the highest standards of excellence.

During this pivotal stage of production, we implement rigorous quality controls to ensure tooling is designed, manufactured and finished to a high standard. This commitment guarantees optimal results and flawless finishing.

At HH Plastic Metal Co., we take great pride in our ability to manufacture accurate tooling with swift turnaround times and reasonable pricing. With our versatile capabilities, we have the capacity to produce tooling of all sizes. Our largest machine is capable of handling tools weighing up to 30 tonnes, showcasing our dedication to serving diverse needs across the industry.

Here at HH Plastics Metal Co., we specialize in offering quality Injection Mold Tool services tailored to the needs of our esteemed clients in the global production and manufacturing industries.

We take great pride in our ability to meet the exacting standards of even the most discerning clients. As a testament to our commitment to excellence, we are honored to provide quality Plastic Injection Mold tooling to renowned luxury brands such as Aston Martin, Bentley, and Apple.

These partnerships are a testament to our dedication to delivering exceptional results that align with the high standards of these prestigious companies.

Our mission is to provide high-quality tooling with meticulous attention to detail.

HH Plastics holds a distinguished position as a leading manufacturer of mold tools within the Automotive industry.

We use the latest techniques in Injection Mold Tooling to create bespoke tooling compatible with a diverse selection of plastics and polymers, tailored to meet each client’s specific requirements.

Drawing upon our extensive expertise in the Mold Tooling sector, we design and manufacture custom tooling capable of producing a wide array of components. Whether it’s the tiniest of intricate parts or the largest body components, our team is equipped to deliver exceptional results.

We offer our clients an extensive range of additional services. These encompass micro to multi-cavity high-precision tooling, as well as expansive single impression tools specifically designed for exterior bodywork.

As dedicated suppliers of Plastic Injection Mold Tooling, we proudly serve esteemed global clients, including Bentley, Aston Martin, Peugeot, McLaren, and Jaguar Land Rover. Our unwavering commitment to delivering quality products and services has earned us the trust and confidence of these prestigious automotive brands.

The electronics industry demands exceptional precision in order to produce mold tooling for small parts. It is with great pride that we have earned the trust and recognition as reputable suppliers of Plastic Injection Mold Tooling to numerous high-profile brands within the consumer electronics sector.

Our commitment to delivering outstanding quality and precision aligns seamlessly with the rigorous standards set by this industry.

At HH Plastic Metal Co. Ltd, we hold extensive expertise in manufacturing high-quality tooling for the home appliances industry.

We are dedicated to upholding the standards set by world-leading Original Equipment Manufacturers (OEMs), ensuring that our clients receive nothing less than the finest quality products and exceptional customer support.

Our custom Injection Mold Tooling service excels in navigating the environmental factors involved in the home appliance market’s design process. We employ Mold Flow Analysis and Design for Manufacturing (DFM) to minimize cycle time, thereby maximizing production efficiency while reducing equipment wear and tear.

Whether you require a multi-cavity tool, a family tool, or large single impression molding, our extensive experience and expertise in the manufacturing industry enable us to deliver precise designs that meet your specifications.

Our commitment lies in surpassing our clients’ expectations, exemplified through our provision of excellent tooling, as well as exceptional management and delivery services that adhere to high-performance criteria. This fundamental value has paved the way for our long-term success and valuable professional relationships with our esteemed global clientele.

Since our establishment in 2013, our manufacturing center has been strategically located in the thriving economic hub of Shenzhen, China.

We take immense pride in adhering to responsible and controlled management practices, coupled with rigorous quality control and the expertise of our professional engineering team. These factors enable us to deliver superior Mold Tooling solutions and provide enhanced customer service to all our valued clients. We are fully registered and compliant with the internationally recognized ISO 9001 standard, specializing in the design and manufacture of high-quality molding tools.

Our comprehensive Injection Mold Tooling service encompasses the entire design and production process, from initial conceptualization to the manufacturing of the tools and associated fixtures. Recognizing the high-volume demands of the manufacturing industries, we offer a standard 500,000 shot tooling guarantee with all our mold tooling solutions.

We confidently make this commitment based on our unwavering dedication to build quality and design excellence, which are integral aspects of our engineering process. Our tools are meticulously crafted to withstand high cycle counts, and we employ only the highest quality steel materials to ensure optimal results are achieved with each use.

Why Choose Us?

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

If You Need A Top-Quality Plastic Mold Factory To Bring Your Ideas To Life, Contact Our Expert Team!

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency