Our Story

What's Our Goal?

Our goal is to offer a complete solution for plastic injection mould design, precise tooling, parts, and associated fixtures.

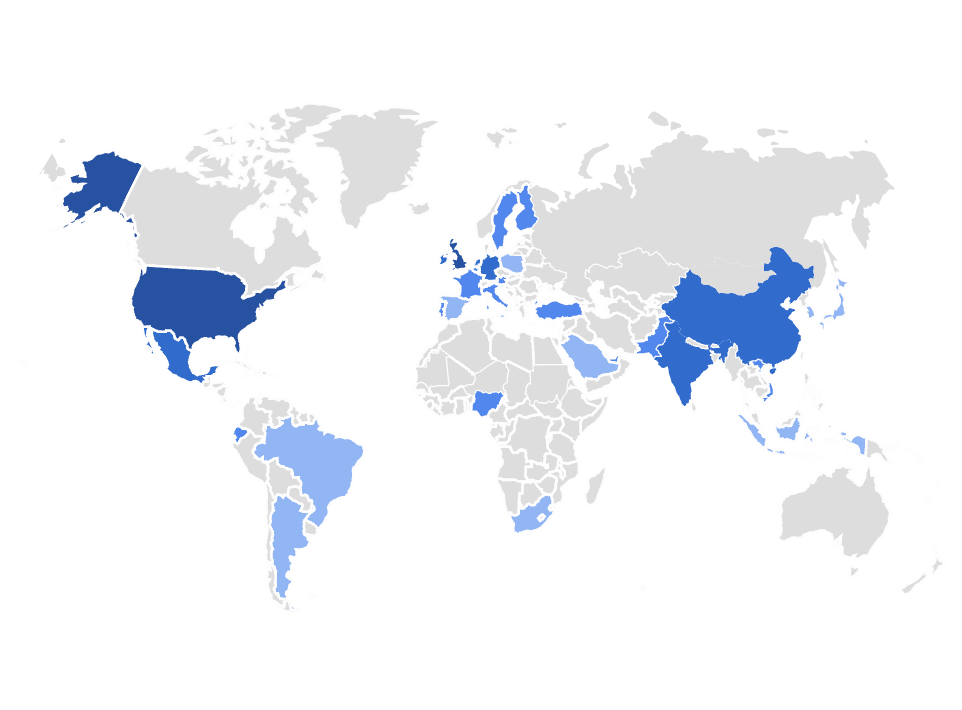

HH Plastic Metal Co., Ltd is an international designer and manufacturer of the highest quality tooling for the plastic injection moulding industry. Based in Shenzhen, our internationally recognised leadership team are on hand to ensure the very highest standards are achieved, and to provide the level of communication our customers have grown to expect.

Industries that we service include Automotive, Medical, Home Appliances and Electronics – all of which demand the highest attention to detail tooling.

AT HH WE STRIVE TO BECOME AN OUTSTANDING SUPPLIER AND PARTNER IN THE INDUSTRY.

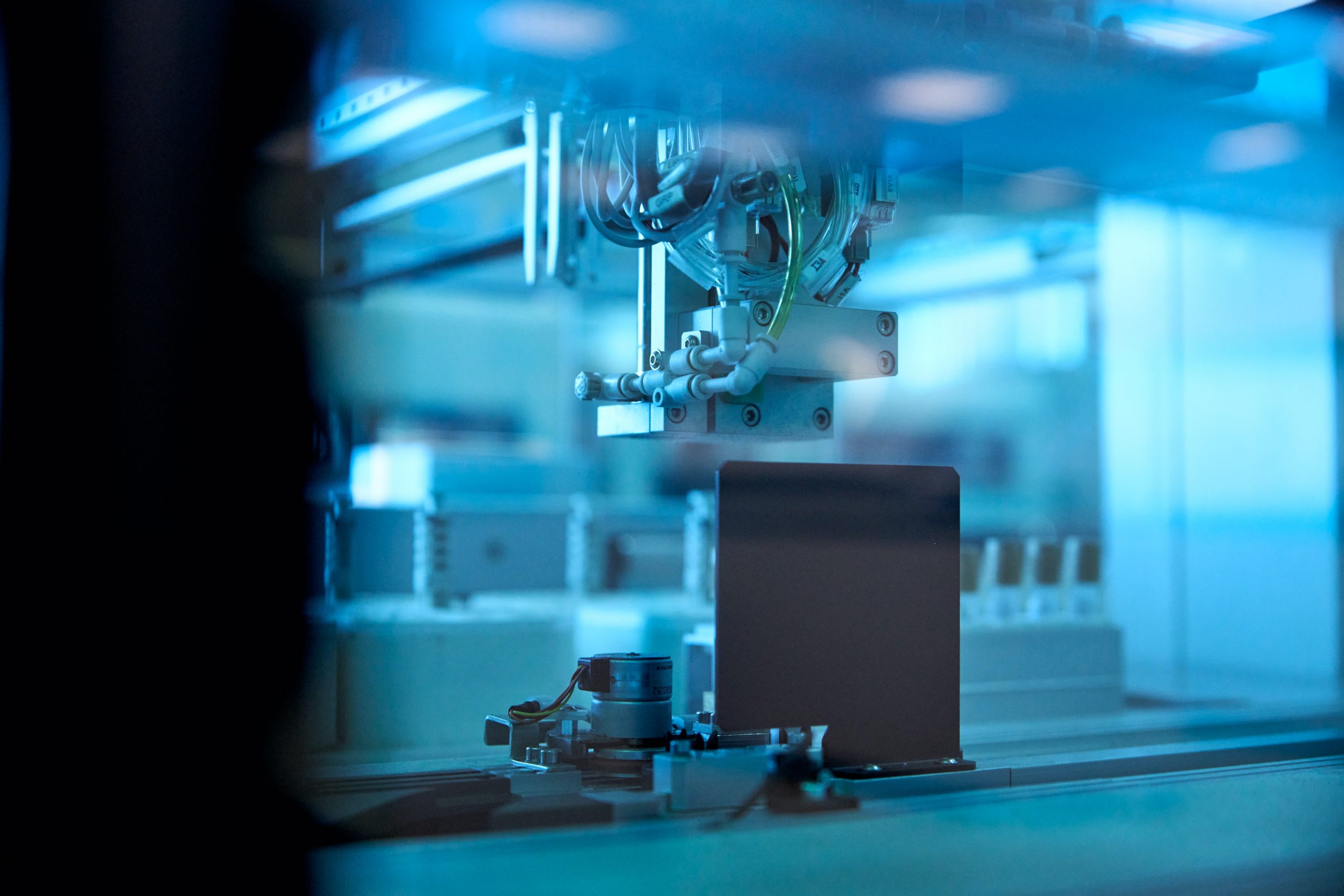

HH Plastics is a modern, well-equipped tool manufacturing facility with a full complement of the latest CNC machinery. Our highly skilled toolmakers and specialist machinists use this equipment to produce high-quality Injection Mould tooling for the Medical, Packaging, Automotive, and Domestic Appliance sectors.

HH Plastics specialises in more sophisticated tooling such as multi-cavity quick cycle tools, 2-Shot technology, and large multi-movement tooling up to 40 Tonnes, with the majority of them incorporating multi-drop and sequential valve gate hot runner systems.

All tooling is designed in-house by our Tool Design Engineers in 3-D using the latest CAD software, Moldflow is performed where necessary, along with full component design feasibility studies to capture any potential issues at the design stage, tool design data is then up-loaded onto our main server, and our Toolroom personnel use modern CNC and measurement equipment to manufacture & inspect mould parts ready for final assembly by our Toolmakers.

Key Features

These are just SOME of our top key features that make HH Plastic Metal the choice for the precision tooling industry :

- Injection mould tools up to 40 tonnes.

- Every part has a complete tooling feasibility report.

- Component designer on staff to assist with revisions and ensure quality and all objectives have been attained.

- Mould flow analysis in-house.

- In China, the production is directed and overseen by the internationally recognised team

- Clean Room facilities for the medical industry.

- ISO 9001:2015 certification.

Our scale, advanced technology, and dedicated workforce enable us to deliver world-class Plastic Injection Mould Tooling, Tool Design, End of Arm Tooling, Gauges and Checking Fixtures. Our commitment to quality and innovation is supported by our extensive facilities, state-of-the-art machinery, and highly skilled team. Here’s an overview of our company’s size and capabilities:

- Facility and Area – Located in a prime industrial hub, HH Plastic Metal Co., Ltd operates from a sprawling, modern facility. Our expansive workspace is meticulously organised to ensure optimal workflow and efficiency. Our facility is designed to accommodate high-volume production while maintaining flexibility for custom projects, ensuring we can meet the diverse needs of our clients.

- Our People – Our team is the backbone of our success. HH Plastic Metal Co., Ltd employs a variety of highly skilled professionals, including engineers, designers, technicians, and support staff. Each team member brings a wealth of experience and expertise, contributing to our reputation for excellence and innovation. Our continuous investment in training and professional development ensures that our team remains at the forefront of industry advancements.

- Advanced Machinery and Technology – At HH Plastic Metal Co., Ltd, we pride ourselves on utilizing the latest technology and state-of-the-art machinery to deliver precision and quality in every project

- High-Precision CNC Machines: Our fleet of CNC machines allows for exacting tolerances and intricate designs, ensuring the highest quality molds and parts.

- Injection Molding Machines: We have a diverse range of injection molding machines at our disposal, with capacities ranging from 50 to 1,000 tons, capable of producing components of various sizes and complexities.

- EDM (Electrical Discharge Machines): Our EDM capabilities enable us to create precise mold components and intricate geometries that are essential for complex designs.

- 3D Printing and Rapid Prototyping: Our cutting-edge 3D printing and prototyping equipment allows for quick and accurate creation of prototypes, facilitating faster design validation and iteration.

- 3D Metal Printing: We leverage advanced 3D metal printing with conforming cooling channels technology to enhance precision and efficiency, ensuring superior heat management and performance in our plastic injection mould tools.

- Automated Assembly Lines: Our automated assembly lines ensure high efficiency and consistency, enabling us to handle large-scale production runs while maintaining strict quality standards.

- Quality Control Equipment: Our comprehensive range of quality control instruments, including CMM (Coordinate Measuring Machines), ensures every product meets our stringent quality criteria.

- Capacity and Production Capability – Our facility’s scale and advanced machinery enable us to handle high-volume production without compromising on quality or delivery times. We are capable of producing over 10,000 molds annually, serving a wide array of industries including automotive, electronics, consumer goods, and medical devices. Our flexible production lines can be swiftly reconfigured to accommodate varying production needs, ensuring we can deliver both large-scale and specialized orders with equal efficiency.