Injection Moulds Design

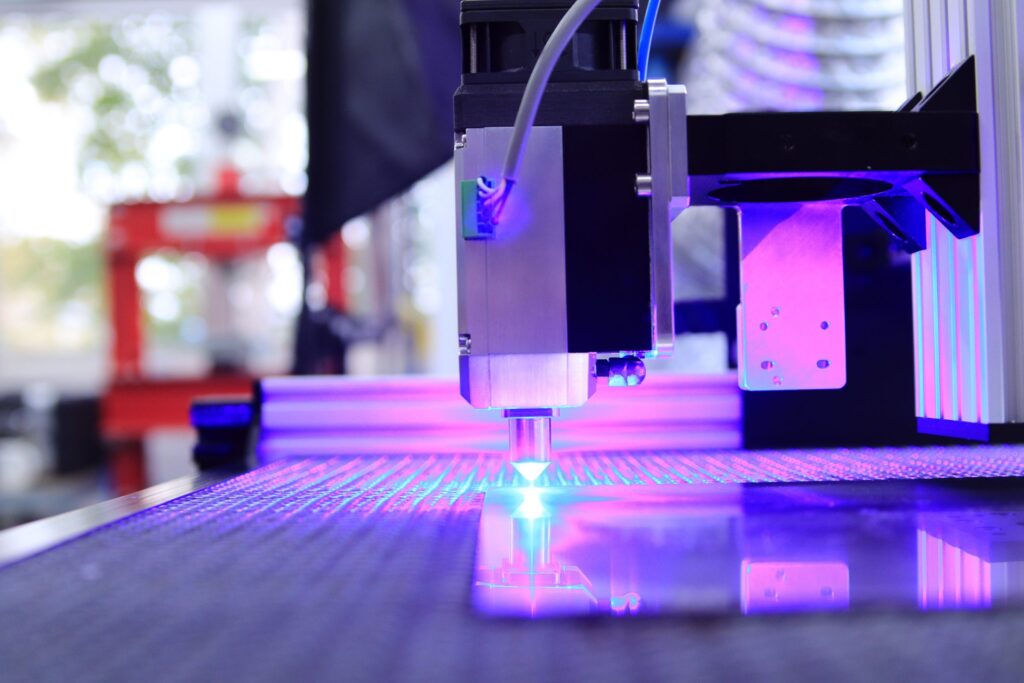

We Provide Top-Quality Injection Moulds Design

At HH Plastic Metal Co. Ltd., we are mould tooling experts who specialise in injection mould design and production for global brands in the Consumer Electronics, Home Appliances, Automotive, Medical, and Electronics industries.

Our team of engineers use the latest technology in Computer Aided Design to create quality injection mould tooling, sensitively tailored to client specifications. Working closely with our Project Managers, our skilled CAD engineers prioritize precision and attention to detail to deliver world-class tooling for our clients.

At HH Plastics, we pride ourselves on offering the highest quality products at competitive prices. Through our global production approach, based in the center of Shenzhen, we are able to provide superior products and services at a fraction of the cost. This has earned us a strong reputation as a trusted provider of mould tooling solutions for renowned clients worldwide.

At HH Plastic Metal Co., we are proud to deliver superior manufacturing services, which stand unmatched in the industry. Our clientele includes high-profile luxury brands that demand no less than exceptional results. We wholeheartedly deliver on our promise to provide high-caliber tooling, paying meticulous attention to detail at each stage of the process.

It is this commitment to excellence that has earned us the trust of influential global brands such as Aston Martin, Bentley, and Apple.

Our mission is to provide high-quality tooling with meticulous attention to detail.

At HH Plastics, we stand unrivalled as leading manufacturers of Mould Tools catering to the Automotive Industry. We use the latest in CAD technology to deliver the highest levels of precision, consistently producing accurate results.

With our state-of-the-art injection moulding techniques, we specialize in producing precision mould tools suitable for a wide range of plastics and polymers. Our expertise extends to manufacturing tools for high-performance engineering, employing innovative methods to ensure exceptional quality.

We meticulously follow product specifications, drawing on our extensive knowledge of mould tooling development. Our CAD design team possesses cutting-edge technology, enabling them to create tooling for both interior and exterior features. From intricate small components to large body parts and bumpers, we have the capacity to fulfil all your design requirements.

Our advanced technology empowers us to offer a comprehensive range of solutions, from micro to multi-cavity high-precision tooling, as well as expansive single impression tools for exterior bodywork.

We take immense pride in our position as trusted suppliers of Plastic Injection Mould Tooling to esteemed brands in the Automotive Industry, including Peugeot, McLaren, and Jaguar Land Rover.

Take a moment to glance around your home or office, and you’ll spot countless devices created using injection moulding technology. From the intricate details on your phone or laptop to the larger electronic components like your television screen, these essential parts are produced en-masse

daily, bringing technology to your fingertips. Each piece requires meticulous care and precision to ensure they meet precise specifications.

Here at HH Plastic Metal Co. Ltd., we manufacture custom tooling for this industry on a global basis. As new electronic advancements emerge at a rapid pace, we find ourselves in high demand from technology industries worldwide – including prestigious brands such as Apple and Bentley.

In the Home Appliance industry, where the volume of produced parts is significant, tooling precision and durability are a high priority. At HH Plastic Metal Co. Ltd, we boast years of experience in manufacturing superior mould tooling for the Home Appliances Industry.

Our commitment to excellence matches the standards set by world-leading OEMs. We prioritize attention to detail, providing the highest quality products, and delivering enhanced customer support to our global clientele. With a deep understanding of the manufacturing process requirements for Home Appliances, our service provides the finest quality tooling in the industry.

We have extensive expertise in selecting the optimal base material for tooling designs. The utilization of high-quality components and precision waterways is essential for effective internal temperature regulation in the tooling. This consideration plays a critical role in reducing the risk of excessive scrap parts during long manufacturing runs.

At HH Plastic, we produce the highest quality moulding tools on the market, which all come complete with a standard 500,000 shot tooling guarantee. Our tools are meticulously designed to withstand high cycle counts, using the highest quality steel to ensure optimal results.

Plus, to guarantee the tool design perfectly suits the application, we conduct comprehensive DFM (Design for Manufacturing) and Mould Flow Analysis. We also offer the option to incorporate specific textures into the finished tool, enhancing the final moulded product’s appearance.

In addition, our customer support and satisfaction are at the heart of our operations. Our professional design service is dedicated to helping you design a manufacturing process that runs smoothly and efficiently, resulting in high-quality plastic injection moulds that meet all your production needs.

For Top-Quality Injection Moulds Design, There Is No Better Option Than Our Expert Team!