Injection Moulding Mould

Contact Us If You Need A Top-Quality Injection Moulding Mould!

At HH Plastic Metal Co., we’re proud to be an injection moulding mould supplier for blue-chip brands in vital industries such as Medical, Electronics, Home Appliances, Automotive, and more.

Operating from our advanced manufacturing facility in Shenzhen, China, our team of over 40 highly skilled engineers leverages cutting-edge Computer-Aided Design (CAD) technology to create custom mould tooling tailored to each client’s unique needs. Every product is designed with meticulous attention to detail and manufactured to the highest quality standards. Throughout the process, our dedicated project managers work closely with clients every step of the way, ensuring flawless execution and results that exceed expectations.

What sets us apart is our global approach to production—allowing us to deliver high-quality tooling with quick turnaround times while maintaining exceptional efficiency. This means our clients receive superior products at competitive prices, without compromising on quality.

We take pride in meeting the demanding quality standards of luxury brands, crafting perfectly finished products that stand out from the competition. Our expertise has earned us the trust of high-profile global leaders such as Apple, Aston Martin, Bentley, and more, making us the go-to choice for premium injection mould tooling.

Why Choose Us To Create Your Injection Moulding Mould?

Plastic injection moulding is at the heart of modern manufacturing, shaping everything from medical syringes to large automotive components and even the intricate parts inside your mobile phone. Every product requires precise design and flawless moulding to function effectively—and that’s where we come in.

At HH Plastic Metal Co., we specialise in crafting custom plastic injection mould tooling for clients across various industries. With over 40 years of experience, we work closely with our clients to develop high-quality, tailor-made moulds that meet their exact specifications. Our collaborative approach ensures that every project is executed with precision, efficiency, and the highest level of craftsmanship.

As a trusted partner to some of the world’s most renowned brands, we are dedicated to upholding exceptional quality control standards and outstanding customer service. We’ve set the benchmark for excellence in the plastic injection moulding industry and continue to innovate, pushing the boundaries of mould technology to drive the future of manufacturing!

Our Injection Mould Tooling Services

Design

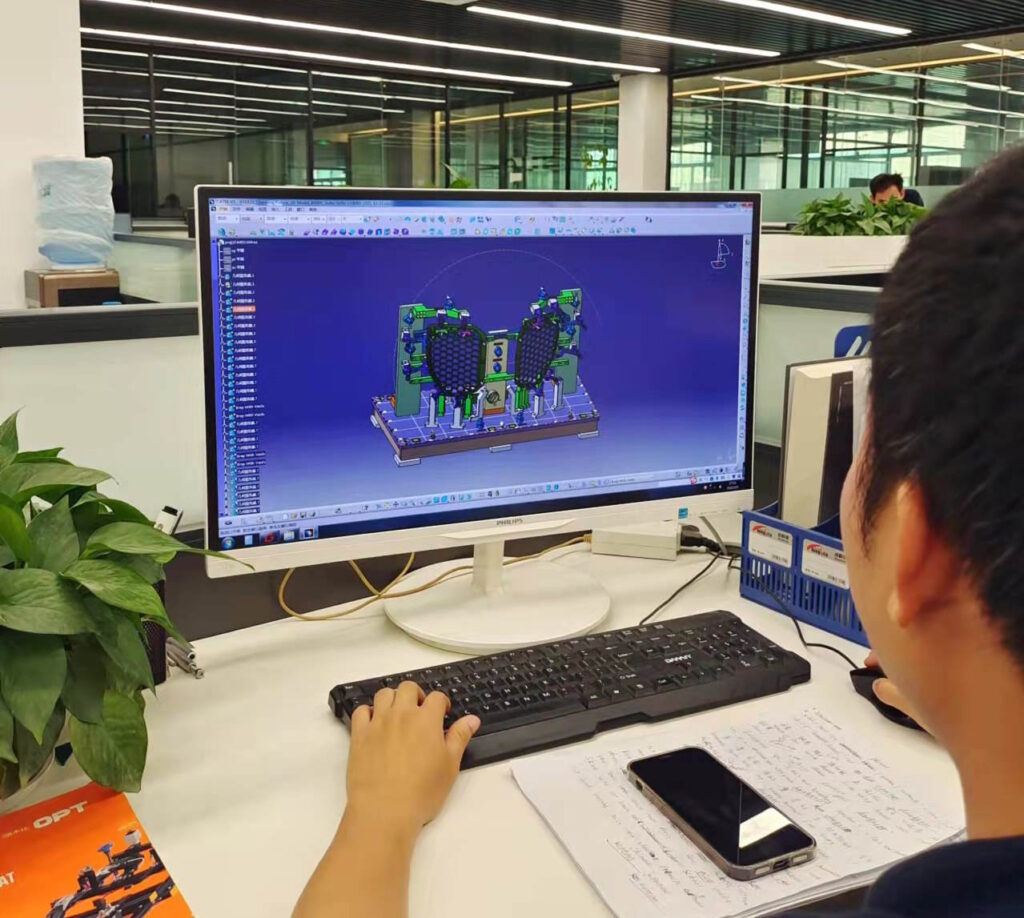

When you partner with HH Plastic Metal Co., you gain access to a team of expert designers and project managers who leverage cutting-edge CAD technology to deliver outstanding results. Our design service harnesses the latest advancements in data transmission, digital modelling, and reverse engineering—helping you bring your vision to life with precision and efficiency.

We know that quality and cost-effectiveness go hand in hand. That’s why we integrate Finite Element Analysis and Mouldflow Analysis into the design process, allowing us to identify and address potential issues early on. By catching problems before production begins, we help you avoid costly revisions, ensuring a smooth, seamless manufacturing experience from start to finish.

CNC Milling

Our facility is equipped with state-of-the-art CNC milling machines, capable of handling tooling up to 40 tonnes with precision and efficiency. Designed for high-volume production, these machines deliver accurate results with fast turnaround times—helping our clients stay ahead in competitive industries.

Behind the scenes, our CNC Milling Department operates through a seamless network link between our design team and shop floor computers. This direct connection allows our machine operators to develop custom machining programs tailored to each project, ensuring smooth communication, efficient workflows, and industry-leading precision.

Every tool we produce undergoes meticulous quality checks, with our skilled operators using advanced software and strict quality control measures to guarantee accuracy and flawless finishes.

Plus, at HH Plastic Metal Co., we believe cost-effectiveness should never come at the expense of quality. That’s why we continuously invest in cutting-edge machining technology and uphold rigorous quality standards—delivering superior tooling that meets and exceeds our clients’ expectations.

Our mission is to provide high-quality tooling with meticulous attention to detail.

About HH Plastic Metal Co.

Founded in 2013, HH Plastic Metal Co. is based in the thriving economic hub of Shenzhen, China. As an ISO 9001-certified company, we specialise in designing and manufacturing high-quality moulding tools that meet the highest industry standards.

We offer a comprehensive service, guiding our clients from the initial design phase through to the production of plastic injection moulds, precision tooling, parts, and related fixtures. By combining cutting-edge international technology with decades of expertise in mould-making, we deliver superior tools that power the manufacturing process.

Over the years, we’ve developed moulding tools for some of the world’s most prestigious automotive brands, including Peugeot, Mercedes-Benz, Jaguar Land Rover, and Bentley. Our commitment to strict quality control, efficient management, and expert engineering ensures that every tool we produce meets our clients’ exact requirements.

At HH Plastic Metal Co., we don’t just create moulds—we build long-term partnerships by providing exceptional craftsmanship, reliable service, and innovative solutions tailored to our clients’ needs.

At HH Plastic Metal Co., we offer a full range of injection mould tooling solutions, designed for precision, efficiency, and reliability.

Here’s what sets us apart:

• Transparent Project Management: Every project is fully managed with structured gateway procedures, ensuring complete visibility and accountability.

• Industry Expertise: Supplying high-quality injection mould tooling to Automotive, Medical, Home Appliance, Electronics, and Packaging industries.

• Precision Engineering: Specialising in CMM & Assembly fixtures and robot fixtures for advanced automation needs.

• Innovative Solutions: Optional 3D-printed steel cores to reduce cycle times and enhance efficiency.

• Comprehensive Feasibility Analysis: Full tooling feasibility studies to ensure optimal performance.

• Global Modification Support: Seamless tooling modifications available in multiple countries.

• High-Capacity Tooling: We manufacture injection mould tooling up to 40 tonnes in weight.

• Expert Design Support: A dedicated in-house component designer for customised solutions.

• Advanced Mould Flow Analysis: In-house mould flow capabilities for precise engineering.

• Dedicated European Technical Support: On-the-ground expertise for European clients.

• ISO 9001 Certified: Committed to the highest quality standards.

• Strategic Location: Based in Shenzhen for easy global access.