Injection Mould Tools

We Create World-Leading Injection Moulding Tooling

At HH Plastic Metal Co., we specialize in the creation of bespoke plastic injection mould tools for clients worldwide in industries such as Consumer Electronics, Home Appliances, Automotive, Medical, and Electronics.

We proudly supply our global client base with quality injection moulding tooling, customized by our team of engineers using the latest Computer-Aided Design technology. Working closely with our Project Managers, our skilled CAD engineers use cutting-edge technology to deliver the highest quality tooling products, with a focus on principles of precision and attention to detail.

HH Plastics is committed to providing the highest quality tooling products at competitive prices. With our global production approach, centered in Shenzhen, we are able to deliver high-quality products and services at a fraction of the cost, making us a trusted provider of Mould tooling solutions for esteemed clients worldwide.

Our services cater to those who require no less than exceptional results. We are committed to supplying high-quality tooling with meticulous attention to detail, solidifying our position as a trusted provider for influential global brands such as Aston Martin, Bentley, and Apple.

Our mission is to provide high-quality tooling with meticulous attention to detail.

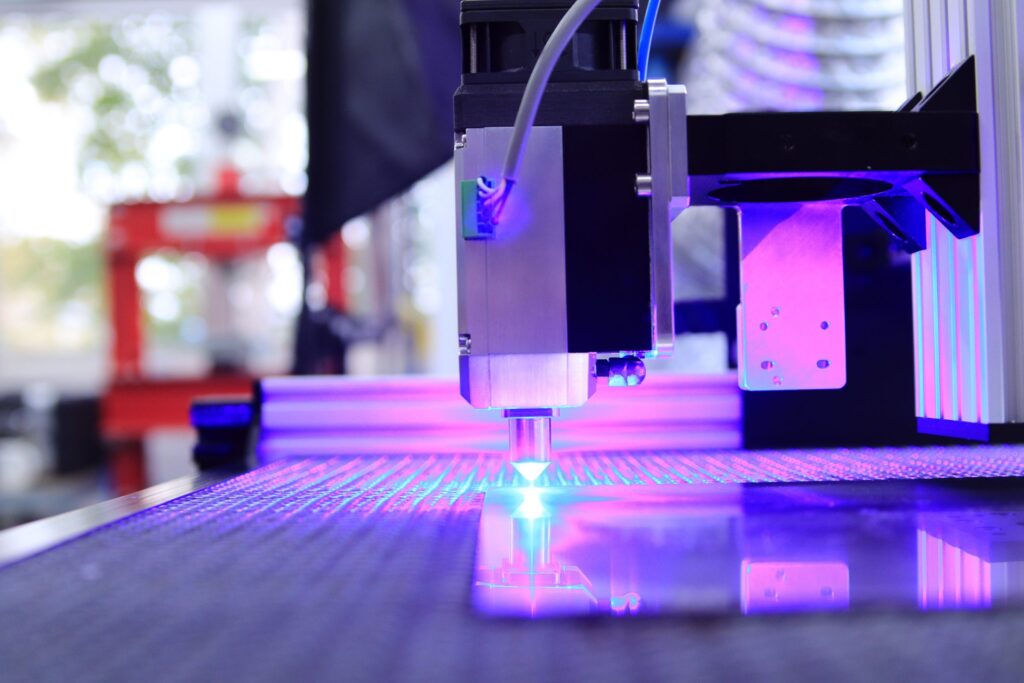

At HH Plastic Metal Co., we are at the forefront of mould tool manufacturing for the Automotive Industry. We are dedicated to producing Mould Tooling with meticulous attention to detail, harnessing revolutionary technology to meet the highest standards of precision.

With our state-of-the-art injection moulding techniques, we manufacture high-precision Mould Tools compatible with a wide range of plastics and polymers, including those used in high-performance engineering.

Our expertise in mould tooling development allows us to produce tooling that precisely meets your specifications. Our CAD design team possesses the technological prowess to create tooling for both interior and exterior automotive features, ranging from intricate small components to large body parts and bumpers.

Using our advanced technology, we can fulfill all your design requirements. Whether you require micro to multi-cavity high-precision tooling or expansive single impression tools for exterior bodywork, we have you covered.

We take great pride in being trusted suppliers of Injection Moulding Tooling to some of the most highly-respected brands in the Automotive Industry, such as Peugeot, McLaren, and Jaguar Land Rover.

In every corner of your home or office, you’ll find devices that are a direct result of injection moulding technology.

From the most minute of detailing on your phone or laptop, to the large electronic components like your television screen, injection moulding plays a vital role in their creation.

Every day, millions of these essential parts are produced to bring the latest technology into your hands. Each piece requires meticulous care and precision to ensure it meets the exact specifications.

As a global manufacturer, HH Plastic Metal Co. Ltd. specializes in crafting customized tooling for this industry. With the rapid emergence of new electronic innovations, we are witnessing a surge in demand from technology sectors worldwide.

We are proud to to supply our bespoke Mould Tooling to some of the most high-profile brands in the Consumer Electronics Industry.

In the Home Appliance industry, having reliable and efficient tooling is crucial to produce the necessary high volume of parts. At HH Plastic Metal Co. Ltd, we are highly experienced in manufacturing high-quality tooling for the Home Appliance sector.

We hold ourselves to the same high standards as world-leading Original Equipment Manufacturers (OEMs). Our attention to detail, commitment to delivering the highest quality products, and provision of exceptional customer support set us apart. With our in-depth understanding of the manufacturing process requirements for Home Appliances, we ensure that our tooling meets the industry’s most stringent quality standards.

We excel in selecting the right base material for tooling design. High-quality components and precision waterways are crucial for effective internal temperature regulation, minimizing the chances of excessive scrap parts during long manufacturing runs.

Environmental considerations are at the forefront of our tooling design for the Home Appliance Market. We conduct Mould Flow Analysis and Design for Manufacturability (DFM) to optimize cycle time, reduce equipment wear and tear, and maximize production efficiency.

Whether you require multi-cavity tooling, family tooling, or large single impression Moulding, our skilled team has the necessary expertise and experience to deliver the right solution, first time.

Our goal is to not only meet but exceed our clients’ expectations by providing quality tooling and outstanding management and delivery services that align with their high-performance criteria. This commitment has fostered long-term success and strong relationships with our esteemed customers.

We take immense pride in being trusted suppliers of Plastic Injection Mould Tooling to a whole host of renowned household brands in the Home Appliances Industry.

We proudly serve a diverse range of industries, including Consumer Electronics, Automotive, Medical, and Electronics.

At HH Plastic, we understand the demands of manufacturing industries, where high-volume production is essential. We are committed to providing our high-profile clientele with durable, high-quality Moulding tools.

Our Mould tooling comes with a standard guarantee of 500,000 shots, as a testament to our commitment to quality. We prioritize build quality and meticulous design throughout our engineering process. Every tool we create is designed to handle high cycle counts and crafted from the finest quality steel, for high-quality results that stand the test of time.

To ensure that our tool design perfectly suits your application, we conduct a full Design for Manufacturability (DFM) and Mould Flow Analysis. We offer the option to incorporate specific textures into the finished tool, creating the perfect effect on the final Moulded product.

At HH Plastic Metal Co., customer support and satisfaction are at the core of our values. Our professional design consultancy service is here to assist you in designing a manufacturing process that operates seamlessly and efficiently, resulting in high-quality plastic injection Moulds tailored to your production needs.

When designing our tooling, we always consider how it will be used in practice, carefully weighing these considerations in every design decision. This meticulous attention to detail allows us to help our customers lower expenses both in the short and long term.

For Injection Mould Tools, There Is No Better Option Than HH Plastic Metal Co.!