Injection Mould Tooling Shenzhen

We Provide Top-Quality Injection Mould Tooling In Shenzhen

At HH Plastic Metal Co., we specialise in designing and creating plastic injection mould tooling in Shenzhen tailored to the needs of our worldwide client base. Our expertise spans across diverse industries such as Customer Electronics, Home Appliances, Automotive, Medical, Electronics, and more.

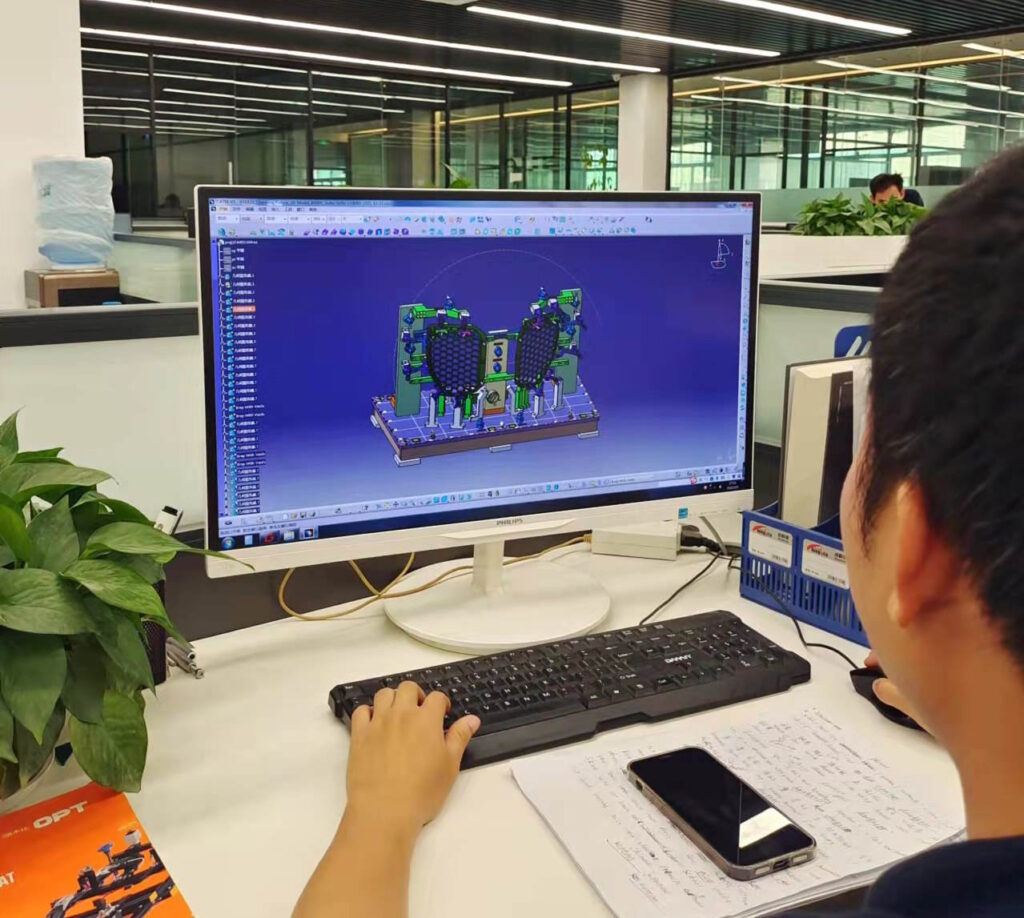

Our team of highly skilled engineers employs cutting-edge Computer Aided Design technology to meticulously create custom plastic injection moulding tooling. Working closely with both our Project Managers and clients, these CAD engineers ensure the production of injection mould tooling that not only meets specifications but also stands out for its remarkable precision, meticulous attention to detail, and stringent quality control.

We utilise a global production strategy that spans from our manufacturing headquarters in the financial centre of Shenzhen, China to our UK-based management team. This approach allows us to deliver top-notch products and services while maintaining cost-efficiency.

It is these core principles that have solidified our reputation as an exceptional supplier of injection moulding tooling to renowned global brands.

About Our Injection Mould Tooling In Shenzhen

As providers of custom plastic injection mould tooling services, we are deeply committed to delivering high standards of quality control to our esteemed clients.

Recognising the importance of maintaining the highest levels of precision and excellence, we are steadfast in our dedication to upholding these values across every facet of our operations.

From the very inception of an idea to the final execution of our services, we ensure a sense of meticulous care and an unwavering commitment to quality.

Our relentless pursuit of excellence extends not only to the technical aspects of our work but also to the relationships we forge with our valued clients. We understand that trust is built upon consistent performance, and thus, we continually strive to meet and exceed the expectations of our blue-chip clientele.

By nurturing a culture that places quality and care at its core, we aim to not only meet industry standards but to set new benchmarks.

It is through this approach that we not only provide exceptional plastic injection mould tooling services but also contribute to the success and growth of the enterprises we serve.

Our injection mould tooling design service brings you cutting-edge capabilities in data transmission, modelling, digitised information, and reverse engineering – all tailored to meet your business’ unique needs.

Our team of skilled CAD engineers uses the latest advancements in computer-aided design and manufacturing to transform your concepts into functional models, all while adhering to the most stringent quality standards.

At the design stage, we provide you with access to images generated from Finite Element Analysis and Mouldflow Analysis. This proactive approach eliminates the need for costly and time-consuming modifications down the line.

By doing so, we save you both precious time and resources, ensuring a seamless and efficient design journey.

In our CNC Milling Department, we’ve established a seamless link between our designers and the shop floor computers, allowing for direct communication. Our team of highly skilled machine operators takes charge of designing their own machining programs.

This integrated setup fosters efficient data transfer and collaboration among all teams. By streamlining this process, we ensure a unified service that maximises efficiency and minimises avoidable errors.

Our CNC Milling Machines are designed for peak efficiency, delivering precise mould tooling with impressive speed. Our proficient operators leverage cutting-edge software and controls to guarantee each machined tool meets the highest standards. Throughout this production phase, we implement rigorous quality checks to ensure flawless results and impeccable finishes.

At HH Plastic Metal Co., we take pride in our ability to produce accurate tooling with swift turnaround times and reasonable pricing. Our production capabilities encompass tools of all sizes, with our largest machine capable of handling tools weighing up to 30 tonnes.

Our Clients

At HH Plastics Metal Co., we specialise in offering injection moulding tool services to clients who require the utmost precision and excellence across the global production and manufacturing sectors.

Our pride stems from the fact that we’ve had the privilege of supplying prestigious quality plastic injection moulding tooling to esteemed luxury brands like Aston Martin, Bentley, and Apple.

Our mission is to provide high-quality tooling with meticulous attention to detail.

HH Plastics stands at the forefront as a leading manufacturer of mould tools tailored specifically for the automotive industry.

Our approach involves harnessing the latest techniques in injection mould tooling. This enables us to fashion tools that cater to a diverse array of plastics and polymers, all aligned with the unique requirements of our valued clients.

What sets us apart is our skill for crafting custom-designed tools that draw from our wealth of experience in the mould tooling field. This expertise allows us to create an expansive spectrum of components – from the tiniest intricate parts to the grandest body components.

We offer an array of supplementary services to our clients. These include everything from micro to multi-cavity high-precision tooling, as well as large single impression tools for exterior bodywork, all designed to meet the precise demands of modern automotive manufacturing.

We take pride in our role as dedicated suppliers of plastic injection mould tooling to prestigious blue-chip clients, including Bentley, Aston Martin, Peugeot, McLaren, and Jaguar Land Rover.

Our commitment to excellence is the cornerstone of our enduring partnerships in the industry!

In the world of electronics, achieving impeccable precision is paramount, especially when crafting mould tooling for intricately designed components.

We take great pride in being the trusted partner for renowned brands within the consumer electronics sector, supplying them with high-quality plastic injection mould tooling.

Injection Mould Tooling For The Home Appliances Industry

At HH Plastic Metal Co. Ltd, our journey spans years of dedicated experience in crafting quality tooling for the home appliances industry.

Our commitment to excellence is not just a claim; it’s a reflection of our dedication to matching the high standards set by world-renowned OEMs. With an unwavering focus on quality, we offer not only exceptional products but also unparalleled customer support to our valued clients.

Navigating the intricate landscape of home appliance market demands, our custom injection mould tooling service brings a nuanced understanding of environmental considerations into the design process. Take, for instance, our approach of integrating Mould Flow Analysis and Design for Manufacturing (DFM) – these measures aren’t just about efficiency; they’re about optimising cycle times, enhancing production output, and ensuring equipment longevity.

From multi-cavity tools to family-oriented designs, as well as large single impression moulding, our wealth of expertise drawn from the manufacturing industries equips us to execute your vision with precision and adherence to specifications.

Our aspiration goes beyond just meeting expectations; it’s about surpassing them. By delivering exceptional tooling alongside impeccable management and delivery services that align with the highest performance standards, we’ve etched a core value that underpins our lasting success.

This very value has formed the bedrock of our enduring partnerships with world-leading clients, bolstering both our reputation and the relationships we hold dear.

Established in 2013, our manufacturing centre is based in the economic heart of Shenzhen, China, while our management team are located in the United Kingdom.

We are proud to maintain a responsible controlled management theory, rigorous Quality Control, and a professional engineering team, which enables us to provide quality mould tooling and enhanced customer service to all our clients.

In addition, we are fully registered under the international ISO 9001 standard, specialising in the design and manufacture of high-quality moulding tools.

We offer a full injection mould tooling design and production service, from the initial design process through to the manufacturing of the tools and associated fixtures.

Plus, since we know that tooling for the manufacturing industries needs to produce high volumes of products, all our mould tooling comes with a full 500,000 shot tooling guarantee as standard.

We can make this promise as build quality and design standards are paramount during our engineering process, while all our tools are designed for a high cycle count and made from the highest quality steel to guarantee optimal results!

Why Choose Us For Injection Mould Tooling In Shenzhen?

• We can manufacture injection mould tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

If You Need Top-Quality Injection Mould Tooling In Shenzhen, Contact Our Expert Team!

• We can manufacture injection mould tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency