Injection Molding Manufacturer

We Are A Top-Quality Injection Molding Manufacturer

At HH Plastic Metal Co., we take great pride in being a world-class plastic injection molding manufacturer. Our clientele spans various global industries, including Medical, Electronics, Home Appliances, and Automotive.

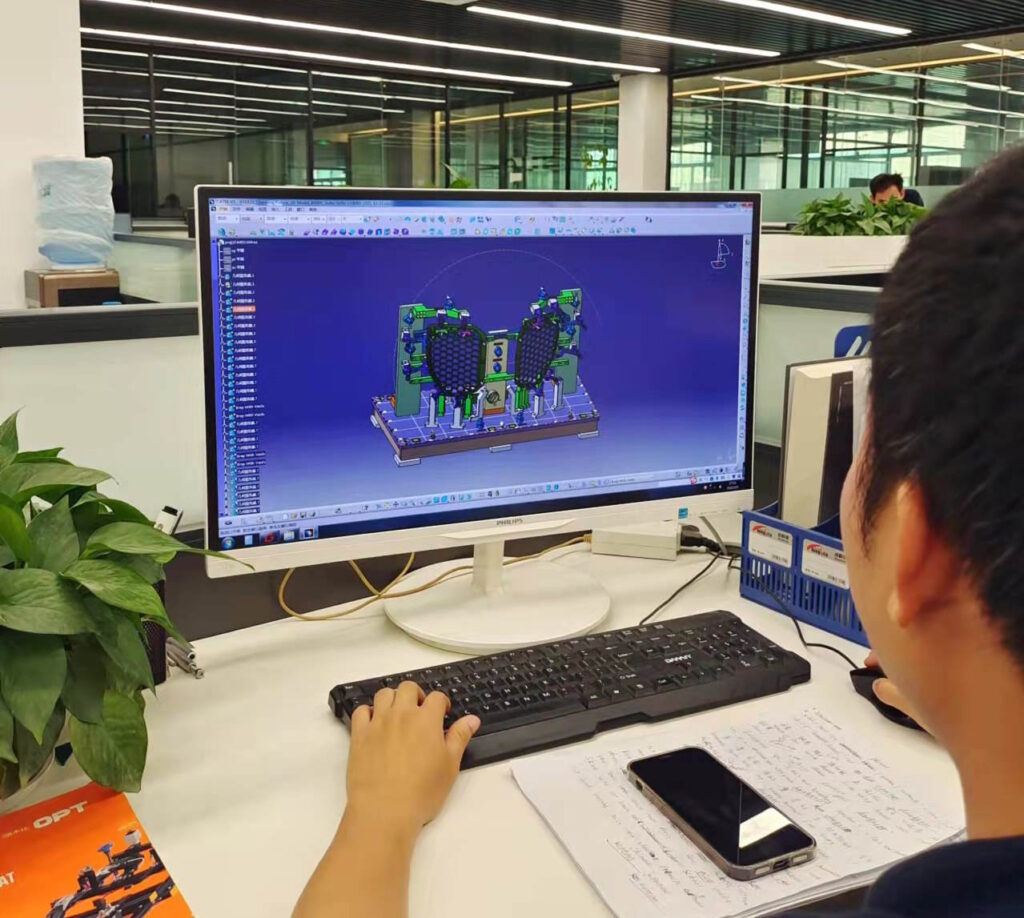

Situated in our expansive manufacturing facility in Shenzhen, China, our team – consisting of over 40 skilled engineers – employs state-of-the-art Computer Aided Design (CAD) technology to craft custom plastic injection mold tooling for clients worldwide.

What sets our plastic injection mold tooling services apart is our global approach to production. This enables us to produce high-quality tooling with swift turnaround times, all while maintaining a strong focus on efficiency at every stage of the production process. This allows us to offer our diverse client base superior-quality tooling at cost-effective rates.

We excel at meeting the demanding quality control standards expected by luxury brands, which is why we’re trusted to design bespoke injection mold tooling by prominent global leaders such as Apple, Aston Martin, Bentley, and more.

Plastic injection molding is a crucial step in the manufacturing process for nearly every product in today’s market. Whether it’s medical equipment like syringes, large automotive components, or the intricate parts of your iPhone, each item must undergo meticulous design and molding to achieve the precision necessary for effective functionality.

Here at HH Plastic Metal Co., we specialize in crafting custom plastic injection mold tooling for clients across a wide array of industries. Drawing from our wealth of experience spanning over 40 years in the plastic injection molding sector, we cater to a diverse range of client needs, tailoring custom tooling to their specifications through close collaboration to attain the desired results.

As a trusted provider of plastic injection mold tooling to globally renowned brands, we are unwavering in our commitment to maintaining exceptional quality control standards and providing exceptional customer service. We’ve set the benchmark for the plastic injection molding industry worldwide and continuously strive to push the boundaries in our relentless pursuit of mold technology advancement.

At HH Plastic Metal Co., we are dedicated to maintaining the utmost precision and rigorous quality control standards throughout our operations. It’s these principles that have paved the way for us to nurture enduring professional connections with esteemed clients spanning a wide array of industries.

When you choose HH Plastic Metal Co., you’ll gain access to a highly skilled team of designers and Project Managers. These professionals harness cutting-edge CAD technology to deliver outstanding results. Through our design service, you can take advantage of the very latest breakthroughs in data transmission, modeling, digitized information, and reverse engineering.

At HH Plastic Metal Co., we recognize that efficiency is paramount for ensuring prestigious quality without compromising on cost. That’s why we provide our clients with access to Finite Element Analysis and Moldflow Analysis visuals during the design phase, effectively eliminating the need for expensive revisions later in the process.

Our facilities are equipped with top-of-the-line CNC Milling machines, capable of producing tooling weighing up to 40 tons. These highly efficient machines are purpose-built for large-scale production and deliver precise tooling with rapid turnaround times.

Behind the scenes, our CNC Milling Department operates via a direct network link connecting our designers with our shop floor computers. Here, our machine operators create customized machining programs for our clients. This setup prioritizes communication and collaboration, facilitating efficient data transfer and ensuring a unified and efficient service.

Our skilled operators employ advanced software and implement stringent quality controls to guarantee that the quality of each completed tool meets our exacting standards. This ensures that every tool is not only highly accurate but finished to a superior standard.

At HH Plastic Metal Co., we firmly believe that cost-effectiveness should never come at the expense of quality. That’s why we remain dedicated to exceeding our clients’ expectations by adhering to strict quality controls and investing in the latest machine tooling technology.

Our mission is to provide high-quality tooling with meticulous attention to detail.

HH Plastic Metal Co., founded in 2013, is situated in the bustling heart of Shenzhen, China. We take immense pride in our full compliance with ISO 9001 regulations and our industry-leading expertise in the design and manufacture of high-quality molding tools.

We offer a complete service to our clients, covering the entire journey from the initial design phase to the fabrication of plastic injection mold designs, precision tooling, parts, and related fixtures.

At HH Plastic Metal Co., we harness advanced international technology alongside our extensive experience in the mold-making industry to create high-quality molding tools for the production process. We have a proven track record of successfully developing tools used in manufacturing components for prestigious automotive clients such as Peugeot, Mercedes Benz, Jaguar Land Rover, Bentley, and more.

Our approach centers around responsible and controlled management principles, rigorous Quality Control, and a dedicated engineering team. This synergy allows us to provide top-notch mold tooling while elevating our customer service to new heights!

Why Choose Us?

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

Contact Us If You Need A Top-Quality Injection Molding Manufacturer!

• Full project managed with gateway procedures to ensure complete visibility and transparency

• We can manufacture injection mold tooling of up to 30 tons in weight

• Optional 3D-printed steel cores to reduce cycle times

• Full support for modifications in various countries

• Dedicated European Support Technical Manager

• Conveniently located in Shenzhen for access

• Dedicated in-house component designer

• Full tooling feasibility provided

• CMM & Assembly fixtures

• In-house mold flow

• ISO 9001 approved

• Robot Fixtures