Injection Mold Companies

We Are A World-Leading Injection Molding Company

HH Plastic Metal Co. are specialist manufacturers of quality plastic injection molding machine tooling for industries including Consumer Electronics, Home Appliances, Automotive, Medical, and Electronics. Our team of engineers, equipped with cutting-edge Computer-Aided Design (CAD) technology, creates bespoke injection mold tooling to meet the specific needs of our clients worldwide.

When you choose HH Plastic Metal Co., you can expect exceptional craftsmanship and attention to detail. Our experienced CAD engineers work closely with our Project Managers to ensure that every product we create is of premium quality. We understand the importance of precision and strive to deliver products that meet the highest standards.

We take pride in offering the best value for your investment. By adopting a global approach to production, from our manufacturing base conveniently situated in the centre of Shenzhen, China, we can provide quality injection mold products and services to global clients at cost-efficient prices.

This has earned us a reputation as trusted providers of mold tooling solutions for a wide range of high-profile clients.

Our mission is to provide high-quality tooling with meticulous attention to detail.

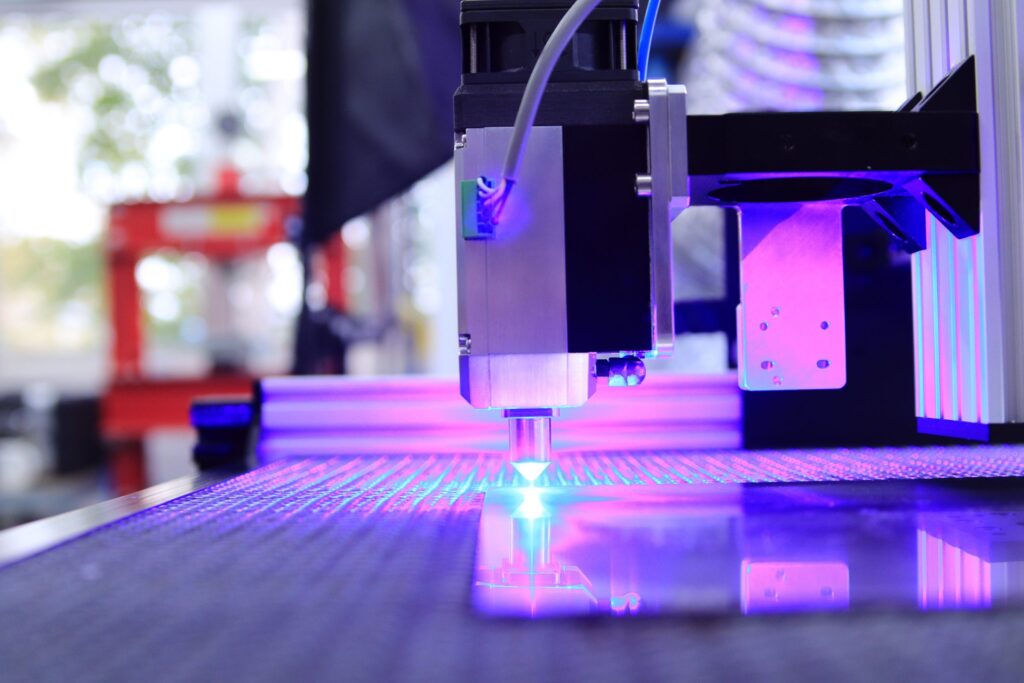

As leading plastic injection mold tool manufacturers for the Automotive Industry, we utilize state-of-the-art techniques to create high-precision mold tools suitable for a variety of plastics and polymers.

Our expertise in design and development allows us to produce tools tailored to almost any specification. Whether you require micro to multi-cavity high-precision tooling or large single impression tools for exterior bodywork, we have the capabilities to meet your needs.

We are honored to have earned the trust of esteemed brands in the Automotive Industry, including Bentley, Aston Martin, Peugeot, McLaren, and Jaguar Land Rover.

Our commitment to excellence and attention to detail make us the go-to choice for Plastic Injection Mold Tooling in the industry.

The influence of injection molding technology is visible in every corner of our homes and offices. From the intricate details on your phone or laptop to the larger electronic components such as television screens, millions of essential parts are produced daily.

At HH Plastic Metal Co. Ltd., we cater to this industry on a global scale, supplying bespoke Plastic Injection Mold Tooling to prestigious Consumer Electronics companies worldwide.

We supply Plastic Injection Mold Tooling to prestigious companies in this sector, with each part undergoing a rigorous process to ensure that it is crafted to the precise specifications required for the seamless functioning of the final products.

This ensures the highest quality standards are met at all times.

With the Home Appliance industry’s high volume of parts production, having reliable tooling is crucial.

At HH Plastic Metal Co. Ltd., we leverage our in-depth understanding of the manufacturing processes to create top-quality tooling that meets the standards set by world-leading Original Equipment Manufacturers (OEMs).

We prioritize attention to detail, produce premium quality products, and provide enhanced customer support to our household-name clients. Our focus on environmental factors ensures that our tooling designs optimize cycle time, reduce wear and tear, and maximize production efficiency.

Whether you require multi-cavity tools, family tools, or large single-impression molding, our skilled team has the experience and expertise to deliver superior products that exceed your expectations.

Our dedication to delivering well-built tools and outstanding customer service has earned us long-term business relationships with our blue-chip customers.

At HH Plastic Metal Co., we understand the importance of producing high volumes of products in manufacturing industries. That’s why all our mold tooling comes with a standard 500,000-shot tooling guarantee.

We are confident that our products deliver on our promise due to our prioritization of build quality and design standards throughout our engineering process. Our tools are designed to withstand high cycle counts and are made from the highest quality steel, ensuring optimal results.

To ensure the suitability of our tool design for the application, we conduct comprehensive DFM (Design for Manufacturability) and Mold Flow Analysis. We offer the option to add specific textures to the finished tool, providing the perfect effect on the molded product.

Customer support and satisfaction are our utmost priorities. Our professional design consultancy service assists you in creating a manufacturing process that runs smoothly and efficiently.

We carefully consider the practical utilization of the tooling during the design phase, allowing us to deliver premium-quality products while minimizing waste and expenses.

If You’re Looking For Top-Quality Injection Mold Companies, There Is No Better Option Than HH Plastic Metal Co.!