Injection Molding Automotive

We Are A World-Leading Injection Molding Automotive Supplier

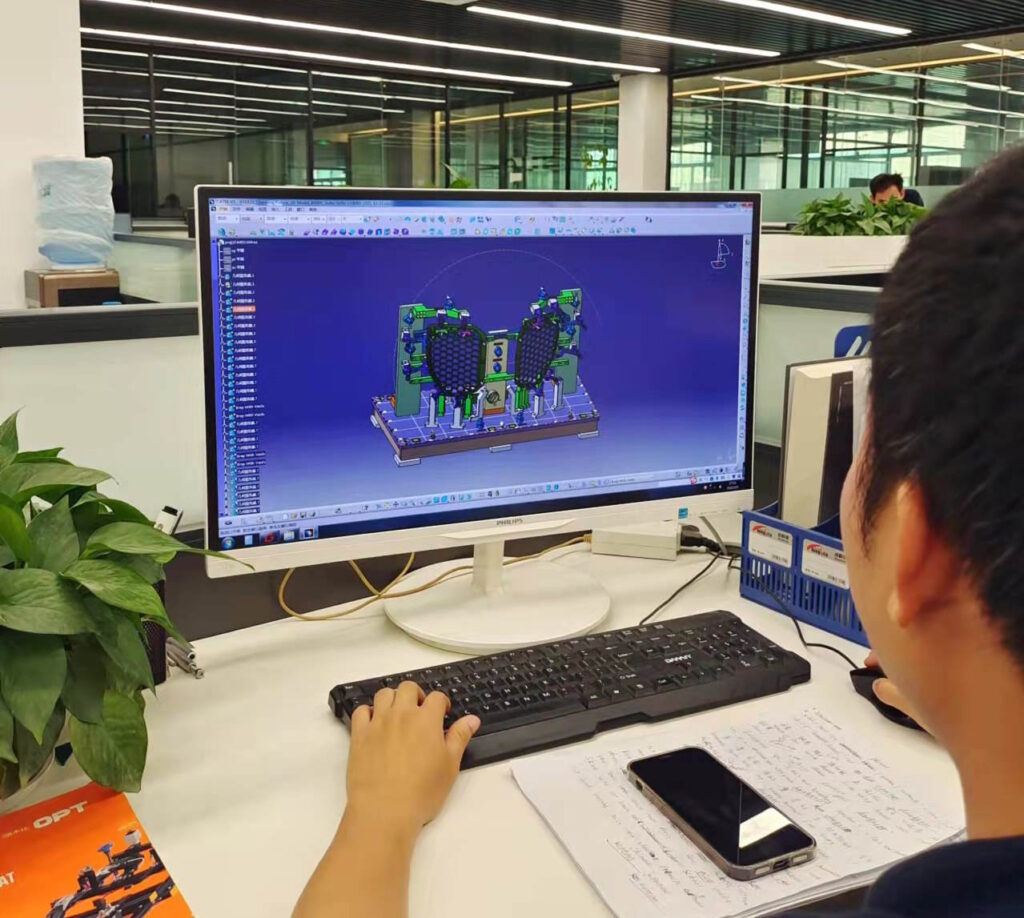

At HH Plastic Metal Co., we specialize in delivering quality injection mold tooling services to our global clientele in the automotive sector. Based in Shenzhen, China, our extensive manufacturing facility is home to a team of over 40 highly skilled engineers who employ the latest in Computer-Aided Design (CAD) technology. Their expertise is dedicated to crafting custom plastic injection mold tooling for renowned automotive brands worldwide.

Each product is meticulously designed and manufactured to meet stringent quality standards, overseen by our vigilant project managers. Collaborating closely with our clients, these Project Managers ensure that every finished product not only meets its intended purpose but also achieves the highest levels of excellence.

We take pride in being at the forefront of the plastic injection mold tooling industry, catering to high-profile automotive clients. Our global approach to production allows us to generate top-quality tooling with rapid turnaround rates, emphasizing efficiency throughout the production process. This efficient methodology has solidified our position as a trusted supplier of plastic injection molding tools at cost-effective rates.

At HH Plastic Metal Co., we are honored to be a reliable provider of plastic injection molding services to luxury automotive brands, counting prestigious names such as Aston Martin and Bentley, among others.

Our Injection Molding Automotive Services

At HH Plastic Metal Co., we take pride in maintaining stringent quality control throughout our design and manufacturing processes. This dedication has distinguished us as a reliable provider of plastic injection mold tooling services for our prestigious clients.

Our design service opens the door for our clients to collaborate with a talented team of over 40 designers and Project Managers. These experts utilize cutting-edge CAD technology to deliver exceptional outcomes for our automotive clients.

Embracing the latest advancements in data transmission, modeling, digitized information, and reverse engineering, our design service ensures quality assurance throughout the design process.

We provide our clients with access to Finite Element Analysis and Moldflow Analysis images during the design stage, eliminating the need for expensive revisions later in the manufacturing process.

At HH Plastic Metal Co., we value clear communication and seamless collaboration throughout our design and manufacturing processes. To achieve this, we’ve established a direct network link connecting our designers to our shop floor computers.

Here, our skilled machine operators craft customized machining programs for our clients. This streamlined structure empowers our teams to facilitate efficient data transfer, ensuring a cohesive and effective service.

We are dedicated to upholding high-quality standards for our clients. By adhering to stringent quality controls and investing in cutting-edge machine tooling technology, we guarantee that each completed tool precisely matches the specifications to meet elevated quality standards.

This not only ensures customer satisfaction but also keeps costs low by minimizing waste during the manufacturing stage.

Founded in 2013, HH Plastic Metal Co. is based in the economic center of Shenzhen, China. Our services cover the entire spectrum, starting from the initial design phase, then progressing through the manufacture and mass production of plastic injection mold design, precision tooling, and associated fixtures.

Leveraging the latest advancements in CAD and mold tooling technology, coupled with our extensive industry experience, we specialize in crafting high-quality molding tools for clients in the automotive sector. Our success is evident in the development of tools used to produce components for esteemed automotive brands like Peugeot, Mercedes Benz, Jaguar Land Rover, and Bentley.

Adhering to a responsible controlled management theory, rigorous Quality Control, and supported by a professional engineering team, we provide high-quality mold tooling and enhanced customer service.

In addition, we are proud to be fully registered under ISO 9001 regulations, specializing in the design and manufacture of high-quality molding tools.

Our mission is to provide high-quality tooling with meticulous attention to detail.

Plastic injection molding plays a crucial role in crafting automotive components, spanning from substantial body parts like bumpers and door panels to intricate elements such as dashboard components, cylinder head covers, and internal components like battery casings and oil gauges.

Beyond being a quality assurance measure, plastic injection molding is pivotal for maintaining the overall excellence of the final product. It ensures a consistent alignment with your design specifications, upholding a high level of precision.

This not only guarantees a flawlessly running vehicle but also fosters high levels of customer satisfaction, contributing to the contemporary appeal of your brand in the ever-evolving automotive market.

In the automotive industry, plastic injection molding extends beyond quality assurance; it is a critical factor in ensuring vehicle safety. By enhancing the accuracy, durability, and consistency of internal components, this process reduces the risk of malfunctions, safeguarding the wellbeing of your customers and upholding the reputation of your brand.

At HH Plastic Metal Co., we boast the capability and technology to manufacture components ranging from the minutest dashboard parts to substantial elements. Our largest machine can handle tooling weighing up to 40 tonnes, showcasing our commitment to versatility and precision in plastic injection molding.

The Advantages Of Plastic Injection Molding In The Automotive Industry

• Highly scalable

• Accurate components

• Enhanced color-matching capabilities

• Improved efficiency at the mass production stage

• Improved lifespan and durability of automotive parts

• Suitable for detailed designs and high-quality finishes

• Rapid tooling techniques ensure fast turnaround at the prototyping stage

Contact Us If You Need A Top-Quality Injection Molding Automotive Company!

- Swift tooling techniques facilitate rapid turnaround during the prototyping stage

- Advanced color-matching capabilities for a polished final product

- Ideal for intricate designs and achieving high-quality finishes

- Prolonged lifespan and enhanced durability for automotive parts

- Highly adaptable to varying production scales

- Streamlined efficiency during mass production

- Precision-crafted components