Injection Mold Tooling Shenzhen

We Provide Top-Quality Injection Mold Tooling In Shenzhen

At HH Plastic Metal Co., we’re a group of specialized designers and manufacturers dedicated to crafting plastic injection mold tooling in Shenzhen for clients worldwide across industries like Consumer Electronics, Home Appliances, Automotive, Medical, and more.

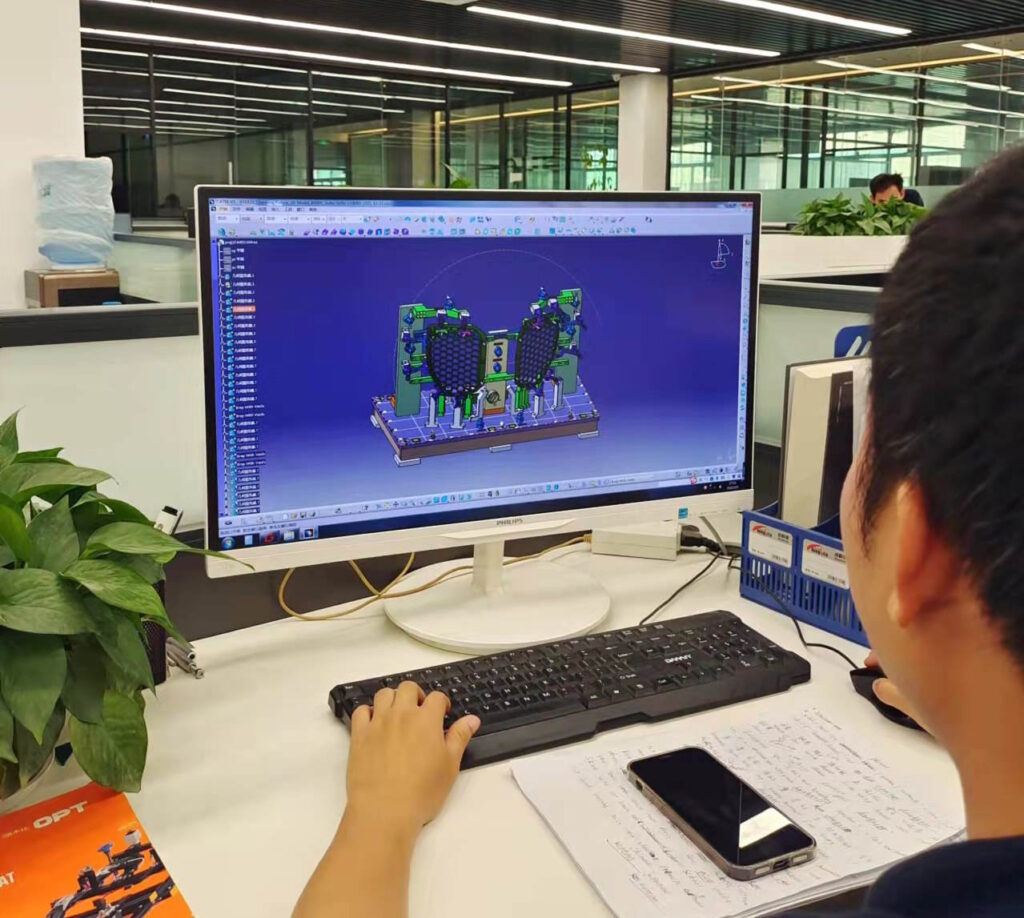

Our team of skilled engineers taps into the latest computer-aided design technology to meticulously craft custom plastic injection molding tooling tailored to the unique needs of our clients around the globe. These CAD engineers collaborate closely with both our Project Managers and clients to produce top-tier injection mold tooling that not only aligns with specifications but shines in terms of precision, attention to detail, and quality control.

With manufacturing facilities located in Shenzhen, China and a UK-based management team, our approach to production has a global perspective, enabling us to provide exceptional products and services at cost-efficient rates.

These principles have solidified our standing as a trusted supplier of injection molding tooling, sought after by renowned global brands for their flagship projects.

About Our Injection Mold Tooling In Shenzhen

As providers of custom plastic injection mold tooling services to esteemed blue-chip clients, we are dedicated to maintaining strict quality control.

This understanding drives our unwavering dedication to upholding the highest benchmarks of quality and attentiveness across every facet of our operations.

Through our injection mold tooling design service, we provide our clientele with cutting-edge capabilities like data transmission, modeling, digitized information, and even reverse engineering.

Our team of skilled CAD engineers employs the latest in computer-aided design and manufacturing processes. This allows us to transform your designs into functional models while upholding the utmost quality standards.

We grant our clients access to images generated from Finite Element Analysis and Moldflow Analysis at the design stage. This proactive approach eliminates the need for costly and time-consuming revisions down the line.

By doing so, we not only save you valuable resources but also ensure a seamless and efficient design journey.

In our CNC Milling Department, things run smoothly with a direct network link connecting our designers to the shop floor computers. It’s here that our highly skilled team of machine operators take charge and craft their own machining programs.

This setup serves us well, ensuring that data flows seamlessly and communication is strong across all teams. By doing so, we’re able to provide a seamless service that ensures high levels of efficiency while eliminating potential errors at an early stage.

Our CNC Milling Machines churn out accurate mold tooling at an impressive pace. Our adept operators make use of advanced software and controls to guarantee each machined tool meets an excellent standard.

As we move through this production stage, we’ve got stringent quality checks in place to ensure that optimal standards and impeccable finishes are maintained.

At HH Plastic Metal Co., we’re truly proud of our ability to create precise tooling quickly and efficiently, at reasonable prices. Our production prowess covers tools of all sizes; in fact, our largest machine can handle tools weighing up to a staggering 30 tons.

Our Clients

Here at HH Plastics Metal Co., we’re all about offering injection molding tool services that cater to prestigious clients who truly value precision and excellence.

We take immense pride in supplying top-tier plastic injection molding tooling to luxury brands such as Aston Martin, Bentley, and Apple. It’s an honor to be a part of their journey toward creating exceptional products.

Our mission is to provide high-quality tooling with meticulous attention to detail.

At HH Plastics, we’re at the forefront of mold tool manufacturing for the automotive industry.

We pride ourselves on using the latest techniques in injection mold tooling to create tools that suit a variety of plastics and polymers, all tailored to our clients’ specific needs.

Our approach involves crafting custom-designed and expertly manufactured tooling, drawing from our extensive experience in the mold tooling field.

We have the know-how to design and produce a wide array of parts, ranging from minute components to the most substantial body parts.

Leveraging our advanced technology, we’re able to offer a comprehensive suite of additional services to our clients. This includes everything from micro to multi-cavity high-precision tooling, as well as expansive single impression tools ideal for exterior bodywork.

Our commitment runs deep as we serve as dedicated suppliers of plastic injection mold tooling to esteemed blue-chip clients such as Bentley, Aston Martin, Peugeot, McLaren, and Jaguar Land Rover.

This partnership speaks to our unwavering focus on delivering exceptional plastic injection molding tool solutions to the automotive industry.

In the realm of electronics, achieving the utmost precision is crucial for producing mold tooling for intricately designed components.

This is why we take immense pride in being the trusted partners that supply plastic injection mold tooling to numerous esteemed brands within the consumer electronics sector. It’s an honor to contribute to the innovation that defines this industry.

Injection Mold Tooling For The Home Appliances Industry

At HH Plastic Metal Co. Ltd, our journey has been defined by years of hands-on experience in crafting quality tooling tailored for the home appliances industry.

We take immense pride in not only matching – but exceeding – the standards set by global industry leaders. Our commitment extends beyond just delivering quality products; it’s about providing impeccable customer support to our valued clients.

Our custom injection mold tooling service is like a compass that expertly guides us through the intricacies of environmental factors during the design process for the home appliance market.

For example, we leverage Mold Flow Analysis and Design for Manufacturing (DFM) strategies to streamline cycle times, ensuring efficient production while minimizing equipment wear and tear.

Whether you require a multi-cavity tool, a family tool, or even crafting large single impression molds, our expertise forged through years in the manufacturing industry ensures your design aligns precisely with your specifications.

Our aim isn’t just to meet expectations; it’s to surpass them.

By delivering exceptional tooling alongside stellar management and delivery services that meet the highest performance benchmarks, we’ve built a core value that underpins our lasting success and fosters enduring relationships with our world-leading clients.

Since our inception in 2013, our manufacturing hub has found its home in the heart of the financial center of Shenzhen, China.

We are proud of our steadfast commitment to responsible management practices. We pair this with rigorous Quality Control and a team of skilled engineers, all of which come together to enable us to deliver quality mold tooling and a truly elevated customer experience to each and every one of our clients.

We’ve earned the esteemed recognition of being fully registered under the international ISO 9001 standard. This underscores our expertise in the design and production of premium-quality molding tools.

Our comprehensive services cover the full journey of injection mold tooling, beginning from the initial design phase and continuing through to the manufacturing of tools and associated fixtures. Recognizing the high-volume needs of the manufacturing sector, we back our work with a solid promise – every single piece of mold tooling comes with a standard 500,000-shot tooling guarantee.

We place immense emphasis on build quality and design standards during our engineering process. At HH Plastic Metal Co., we engineer our tools to withstand extensive cycles, crafted from the finest quality steel to ensure the best possible results.

Why Choose Us For Injection Mold Tooling In Shenzhen?

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

If You Need Top-Quality Injection Mold Tooling In Shenzhen, Contact Our Expert Team!

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency