Injection Mold Design

We Provide Top-Quality Injection Mold Design And Production For Businesses Around The World

HH Plastic Metal Co. are a specialist designer and manufacturer of plastic injection mold tooling for our global clients in the Customer Electronics, Home Appliances, Automotive, Medical, and Electronics industries.

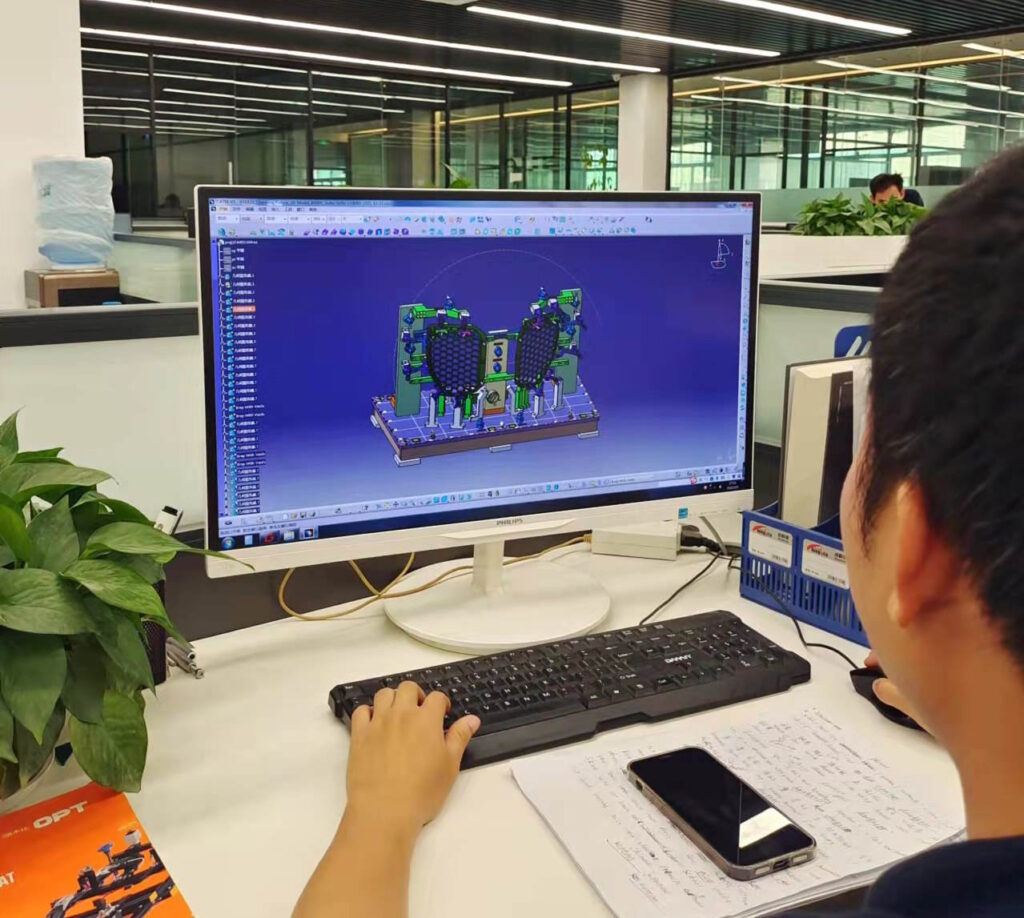

Our team of skilled engineers use the latest in Computer Aided Design technology to create bespoke plastic injection molding tooling for our worldwide client base. These CAD engineers work closely with our Project Managers and clients to produce quality injection mold tooling designed to specification with unrivaled levels of precision, attention to detail, and quality control.

From our base in Shenzhen, China, we use a global approach to production that enables us to deliver high-quality products and services at cost-efficient prices; it is through these values that we have earned our reputation as a trusted supplier of injection molding tooling for high-profile global brands.

As suppliers of custom plastic injection mold tooling services for blue-chip clients, we understand the importance of rigorous quality control.

That’s why we are committed to delivering the highest standards of quality and care throughout every aspect of our business.

Our injection mold tooling design service offers our clients the latest in data transmission, modelling, digitized information, and reverse engineering.

Expert CAD engineers will use the latest in computer-aided design and manufacturing processes to turn your designs into working models while maintaining the highest quality standards.

We offer our clients access to Finite Element Analysis and Moldflow Analysis images at the design stage, which eliminates the risk of having to make expensive and time-consuming changes later on.

This prevents our clients from wasting valuable time and money and ensures a smoother, more efficient design process.

Our CNC Milling Department is run by a direct network link from our designers to the shop floor computers, where our highly skilled team of machine operators build their own machining programs.

This structure enables us to promote effective data transfer and communication between all teams, delivering a cohesive service by maximizing efficiency and preventing unnecessary errors.

Our CNC Milling Machines are highly efficient, producing accurate mold tooling at a rapid pace. Meanwhile, our skilled operators employ state-of-the-art software and controls to ensure that every machined tool is finished to an excellent standard. During this stage of production, we use rigorous quality controls to guarantee optimal standards and flawless finishing.

At HH Plastic Metal Co., we are proud to manufacture accurate tooling at a fast turnaround rate, for reasonable prices. We have the capacity to produce tooling of all sizes, with our largest machine able to handle tools up to 40 tonnes in weight.

At HH Plastics Metal Co., we provide injection molding tool services for the most discerning clients operating worldwide in the production and manufacturing industries.

For instance, we are proud to deliver quality plastic injection molding tooling used in the production of components for luxury brands including Aston Martin, Bentley, and McLaren.

Our mission is to provide high-quality tooling with meticulous attention to detail.

HH Plastics are leading mold tool manufacturers for the automotive industry.

We use the latest injection mold tooling techniques to create tools for use with a wide choice of plastics and polymers, depending on the needs of the client.

Our tooling is custom designed and manufactured using our years of expertise in the mold tooling industries, and we can design and produce a wide range of parts – from the most minute of small components, to the largest of body parts.

Using our advanced technology, we offer our clients a wide range of additional services, including micro to multi-cavity high-precision tooling, and vast single impression tools for exterior bodywork.

We are committed suppliers of plastic injection mold tooling to blue-chip clients including Bentley, Aston Martin, Peugeot, Mclaren, and Jaguar Land Rover

Using our expertise in the design and development of mold tooling, we can produce tools to almost any specification.

For instance, our 40-strong CAD design team has the technology and the skillset necessary to develop tooling for the production of both interior and exterior automotive features, ranging from the most intricate of small components, to extra-large sized body parts and bumpers.

So whether you need micro to multi-cavity high-precision tooling, or vast single impression tools for exterior bodywork, we can meet your requirements.

We are proud that many of the most esteemed brands in the Automotive Industry trust us to be their suppliers of Plastic Injection Mold Tooling; just some of the companies that we have worked with include Bentley, Aston Martin, Peugeot, Mclaren, and Jaguar Land Rover.

The electronics industry requires the highest standards of precision to create mold tooling for the most intricate of parts.

That’s why we are proud to be trusted suppliers of plastic injection mold tooling to many prestigious brands in the consumer electronics industry.

At HH Plastic Metal Co. Ltd, we have years of experience producing high-quality tooling for the home appliances Industry.

We rival the standards of world-leading OEMs, providing the finest quality products and customer support to our clients.

Our custom injection mold tooling service expertly navigates environmental factors during the design process for the home appliance market.

For instance, we deliver Mold Flow Analysis and Design for Manufacturing (DFM) to help keep the cycle time to a minimum, allowing us to maximize production while reducing wear and tear to equipment.

Whether your specification is for a multi-cavity tool, family tool, or large single impression molding, we can use our expertise and experience in the manufacturing industries to deliver your design correct to specification.

We aspire to exceed our clients’ expectations by providing excellent tooling and outstanding management and delivery services to meet high-performance criteria.

This core value has enabled us to secure long-term success and valuable professional relationships with our world-leading client base.

Established in 2013, our manufacturing center is based in the economic heart of Shenzhen, China, while our management team are located in the United Kingdom.

We are proud to maintain a responsible controlled management theory, rigorous Quality Control, and a professional engineering team, which enables us to provide quality mold tooling and enhanced customer service to all our clients.

In addition, we are fully registered under the international ISO 9001 standard, specializing in the design and manufacture of high-quality molding tools.

We offer a full injection mold tooling design and production service, from the initial design process through to the manufacturing of the tools and associated fixtures.

Plus, since we know that tooling for the manufacturing industries needs to produce high volumes of products, all our mold tooling comes with a full 500,000 shot tooling guarantee as standard.

We can make this promise as build quality and design standards are paramount during our engineering process, while all our tools are designed for a high cycle count and made from the highest quality steel to guarantee optimal results!

Why Choose Us?

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

If You Need Top-Quality Injection Mold Design, Contact Our Expert Team!

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency