In high-volume automotive injection moulding, parts don’t just need to be moulded to spec — they must be handled, trimmed, and validated with precision before they ever reach final assembly. That’s where End of Arm Tooling (EOAT) plays a critical role.

When EOAT is designed and manufactured by the same team that engineers the mould tool, you achieve an integrated solution that ensures dimensional accuracy, protects Class-A surfaces, and drives down cycle times.

EOAT Design Principles in Automotive Applications

- Datum Control & Orientation: EOAT must pick the part consistently from the mould, referencing critical datums so downstream operations (trimming, welding, or assembly) remain accurate.

- Part Sensitivity: Many automotive trims have high-gloss or painted Class-A surfaces. EOAT uses vacuum cups, soft-touch pads, or contoured nests to grip non-visible areas, preventing cosmetic defects.

- Balance Between Rigidity & Compliance: EOAT needs rigidity for precision, but also controlled compliance (through flex joints or spring-loaded grippers) to accommodate minor part variation without damage.

- Quick-Change Adaptability: Automotive programs often require rapid tool changes. EOAT with modular quick-change couplers enables fast swaps without rewiring or recalibration.

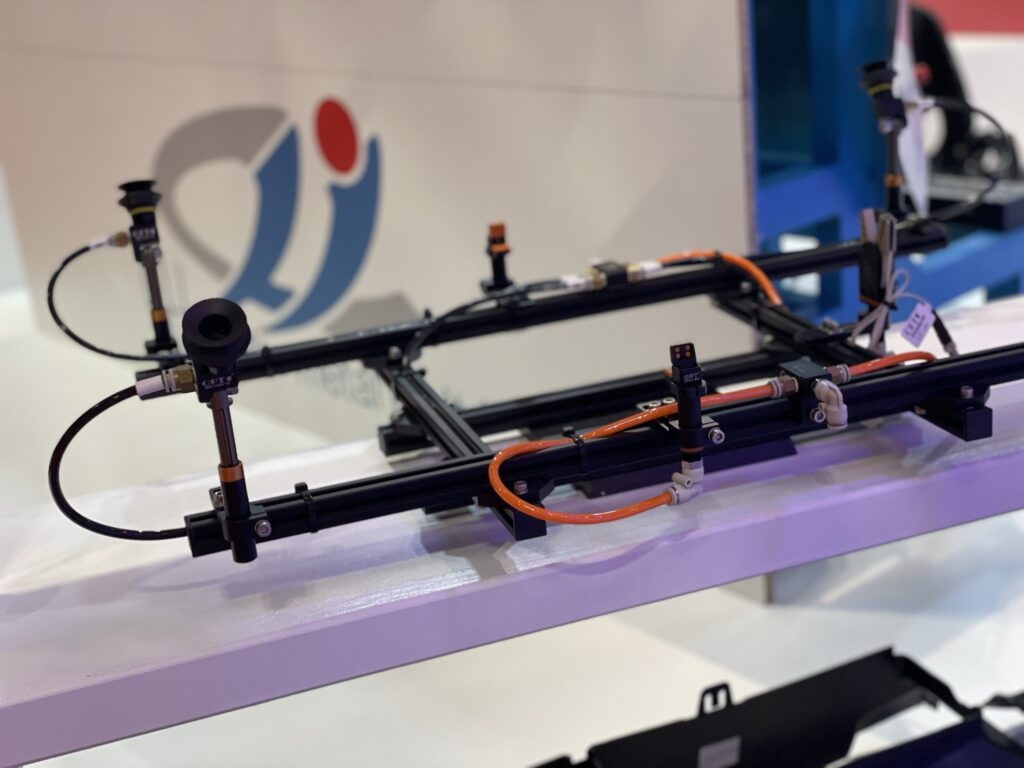

EOAT Mechanisms & Functions

- Vacuum Systems: For lightweight interior parts, custom-shaped suction cups provide gentle yet firm extraction.

- Pneumatic/Electric Grippers: Used for structural parts (e.g., brackets, consoles) where controlled clamping force is required.

- Degating/Deflashing Units: Pneumatic knives, rotary cutters, or hot-blade trimmers integrated into EOAT remove runners and gates directly after demoulding.

- Sensor Integration: Proximity sensors, part presence sensors, and vision cameras embedded in the EOAT provide real-time confirmation of correct handling.

- Multi-Tasking End Effectors: Some EOAT combine pick-up, trimming, and inspection in a single cycle, optimising takt time.

Example: Automotive Door Panel

A door panel requires careful handling and trimming before downstream assembly:

- Primary Grip: Vacuum cups mounted on non-visible ribs extract the panel without marking Class-A surfaces.

- Secondary Operations: Pneumatic blades degate overflow and trim edges.

- Quality Check: A small camera integrated in the EOAT inspects clip features for flash or incomplete fill.

- Placement: The EOAT positions the part directly into a fixture for foam-in-place or welding — all in one robotic movement.

This seamless handling system ensures the panel exits the mould assembly-ready, reducing manual rework and ensuring compliance with OEM dimensional requirements.

Why EOAT from the Tooling Manufacturer Matters

When the tooling company also engineers the EOAT:

- Geometry Alignment: EOAT is built around the exact CAD of the mould tool and part, ensuring perfect datum referencing.

- Process Synergy: Mould ejection and EOAT removal are co-engineered, reducing risk of part deformation.

- Data Continuity: Integrated sensors in EOAT can feed into the same SPC/QA framework used for part validation.

- Commissioning Efficiency: A single-source solution reduces debugging loops and shortens the time to stable production.

In summary:

End of Arm Tooling is not an afterthought — it is an engineered system that integrates with mould design, GD&T requirements, and downstream automation. In the automotive plastic injection moulding sector, EOAT designed by the tooling manufacturer is a critical enabler of precision, repeatability, and zero-defect manufacturing.