Custom Plastic Moulding

We Provide Top-Quality Custom Plastic Moulding Services

At HH Plastic Metal Co., we are providers of high-quality custom plastic moulding services, catering to clients worldwide across the Medical, Electronics, Home Appliances, and Automotive sectors.

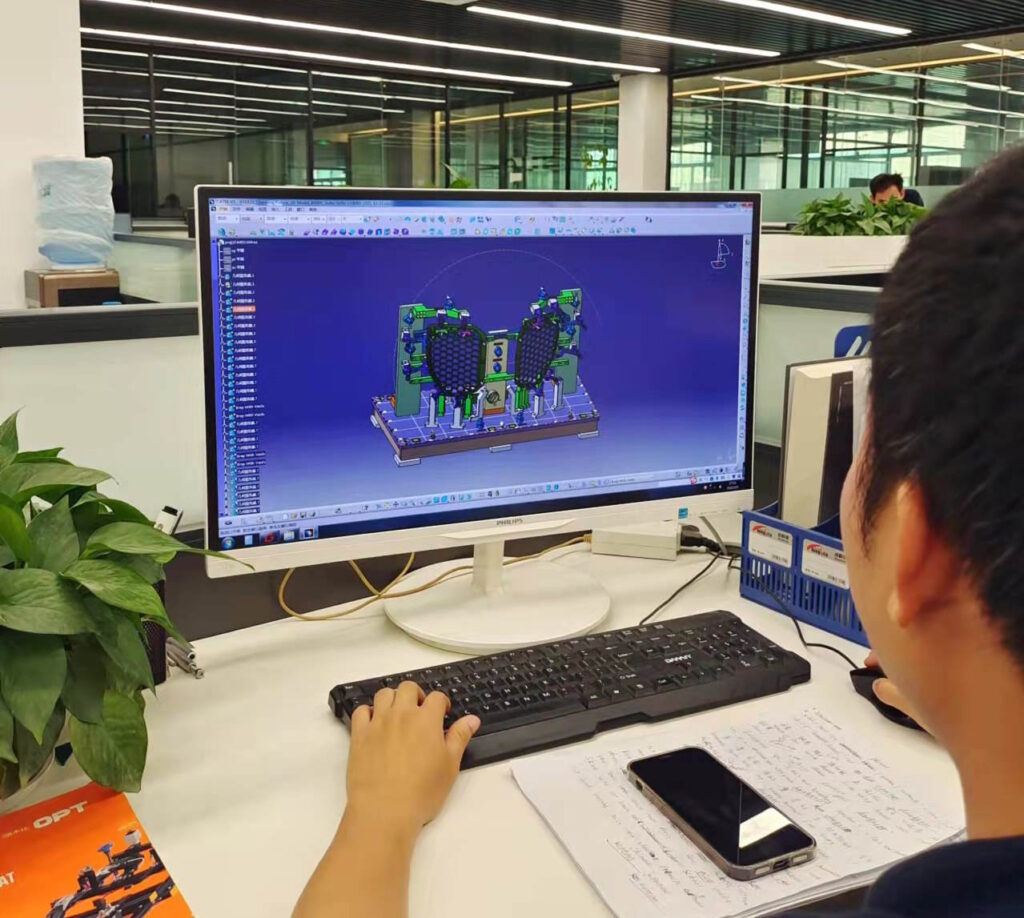

Situated in our state-of-the-art manufacturing facility in Shenzhen, China, our dedicated team of over 40 skilled engineers harness cutting-edge Computer-Aided Design (CAD) technology to craft bespoke plastic injection moulding tools for clients across the globe.

Every product we produce is meticulously crafted to precise specifications and manufactured to the highest quality standards, all under the vigilant guidance of our project managers. They maintain close collaboration with our clients throughout the design and manufacturing processes to ensure impeccable results.

We specialise in meeting the exacting quality control standards demanded by prestigious brands to produce flawlessly finished products. As a result of our dedication, we have earned a position as trusted providers of plastic injection moulding tooling for renowned global brands such as Apple, Aston Martin, Bentley, and more.

Plastic injection moulding is an essential stage in the production of virtually every modern product. From essential medical devices like syringes to large automotive components and the intricate parts of your iPhone, each item demands meticulous design and moulding to achieve the necessary precision to create a functional product.

At HH Plastic Metal Co., we specialise in crafting custom plastic injection moulding tools tailored to the unique needs of clients from a diverse range of industries. Using our extensive experience gained over decades in the plastic injection moulding field, we collaborate closely with our clients to create bespoke tooling that aligns with their specific requirements.

As a trusted provider of plastic injection moulding tools to renowned global brands, we are unwavering in our commitment to upholding exceptional quality control standards and delivering impeccable customer service. We have established the benchmark for the plastic injection moulding industry worldwide and continue to relentlessly pursue moulding technology advancement.

At HH Plastic Metal Co., we are committed to maintaining rigorous quality control standards across all aspects of our operations. These values have not only shaped our work but also fostered enduring professional partnerships with leading clients from a wide spectrum of industries.

When you choose HH Plastic Metal Co., you will be granted access to our talented team of designers and Project Managers, who harness cutting-edge CAD technology to deliver outstanding outcomes. Through our design service, you can harness the latest breakthroughs in data transmission, modelling, digitised information, and reverse engineering for optimal results.

At HH Plastic Metal Co., we hold efficiency paramount, enabling us to achieve prestigious quality products while keeping costs down. We provide our clients with access to Finite Element Analysis and Mouldflow Analysis images during the design phase, eliminating the need for costly revisions down the road.

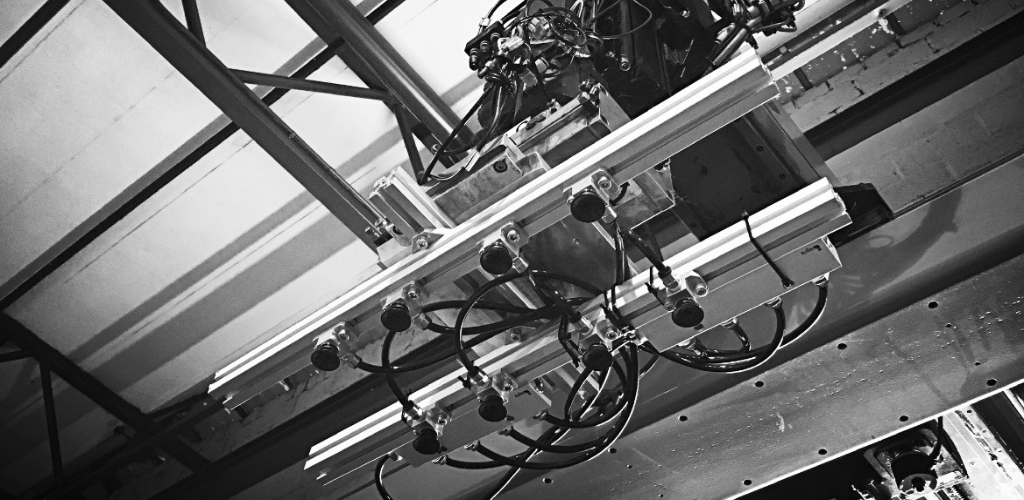

Our facilities boast cutting-edge CNC Milling machines, capable of crafting tooling weighing up to 40 tonnes. These highly efficient machines are purpose-built for large-scale production, delivering precise tooling with rapid turnaround times.

Behind the scenes, our CNC Milling Department operates via a direct network connection, seamlessly linking our designers with the shop floor computers. Here, our skilled machine operators develop custom machining programs for our clients. This setup supports communication and collaboration, facilitating efficient data transfer and ensuring a unified and streamlined service.

Our expert operators use advanced software and rigorous quality checks to guarantee that every finished tool meets our exacting quality standards. This ensures each tool is not only highly accurate but also finished to a superior standard.

At HH Plastic Metal Co., we believe that cost-effectiveness should never compromise quality – that’s why we are fully committed to exceeding our clients’ expectations through stringent quality controls and investments in state-of-the-art machine tooling technology.

Our mission is to provide high-quality tooling with meticulous attention to detail.

HH Plastic Metal Co., founded in 2013, is situated in the thriving hub of Shenzhen, China. We take great pride in our full compliance with ISO 9001 regulations in the design and manufacture of quality plastic injection moulding tooling.

We offer a comprehensive service to our clients, encompassing the entire process from the initial design phase to the manufacture of plastic injection mould designs, precision tooling, parts, and the necessary fixtures.

Harnessing the power of cutting-edge technology, in tandem with extensive expertise in the injection moulding sector, we create bespoke moulding tooling for the manufacturing industry. We’ve been involved in the successful development of numerous tools used in creating components for renowned automotive clients like Peugeot, Mercedes Benz, Jaguar Land Rover, Bentley, and more.

Our philosophy revolves around responsible and controlled management principles, rigorous Quality Control, and a dedicated engineering team. This combination empowers us to deliver high-calibre mould tooling and exceptional customer service to our valued clients.

Why Choose Us

• We can manufacture injection mold tooling of up to 30 tonnes in weight

• We offer full tooling feasibility

• We are ISO 9001 approved

• We provide full support for modifications in various countries

• We have dedicated UK-based support staff and technical managers

• We are conveniently located in the heart of Shenzhen

• We use optional 3D-printed steel cores to reduce cycle times

• We have a minimum 500,000 shot tooling guarantee on all our products!

• We offer full project management with gateway procedures to ensure complete visibility and transparency

Contact Us If You Need Top-Quality Custom Plastic Moulding Services!

• We can manufacture injection mould tooling of up to 30 tonnes in weight

• Optional 3D-printed steel cores to reduce cycle times

• Full support for modifications in various countries

• Dedicated European Support Technical Manager

• Conveniently located in Shenzhen for access

• Dedicated in-house component designer

• Full tooling feasibility provided

• CMM & Assembly fixtures

• In-house mould flow

• ISO 9001 approved

• Robot Fixtures