Automotive Tooling

We Provide Top-Quality Automotive Industry Tooling

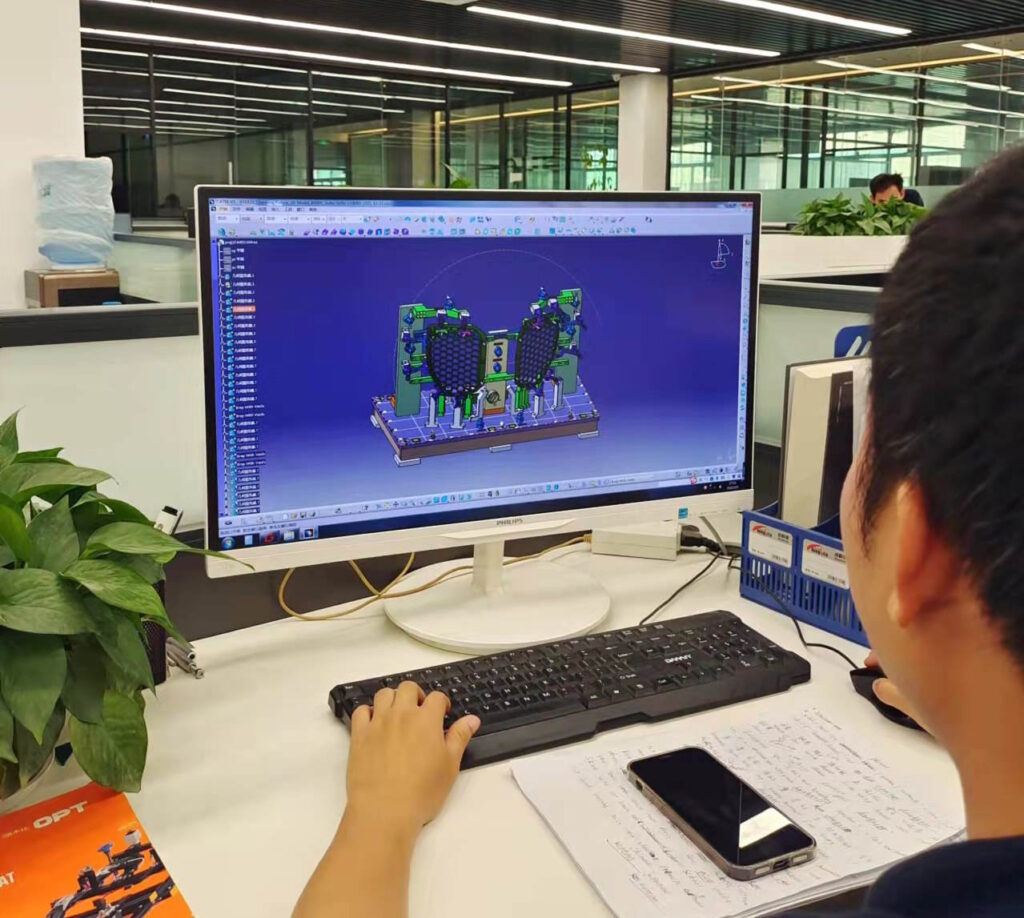

At HH Plastic Metal Co., we are a specialist provider of high-quality plastic injection molding services for our global clients in the automotive industry. We maintain an extensive manufacturing facility in Shenzhen, China, where our team of over 40 highly skilled engineers harness the latest in Computer-Aided Design (CAD) technology to create automotive tooling for world-class brands.

Working to specification, each product is designed and manufactured according to rigorous quality standards, under the careful supervision of our project managers. Our Project Managers collaborate closely with our clients to ensure each finished product is not only fit for purpose, but finished to the highest standard.

We are proud to be a leading force in the delivery of plastic injection molding tools for high-profile automotive clients. We maintain a global approach to production, which enables us to produce top-quality tooling at fast turnaround rates, with a focus on promoting efficiency throughout the production process.

At HH Plastic Metal Co., we are proud to be a trusted provider of plastic injection molding services to luxury brands in the automotive industry, including such high-profile names as Aston Martin, Bentley, and many more.

At HH Plastic Metal Co., we are proud to uphold the highest standards of precision and rigorous quality control at every stage of our design and manufacturing processes.

This commitment has set us apart as a trusted provider of plastic injection molding services to our valued blue-chip clients. The following are just some of the services we offer:

Our design service grants our clients access to a skilled team of over 40 designers and Project Managers. These professionals leverage state-of-the-art CAD technology to achieve superior results for our automotive clients.

Our design service harnesses the latest advancements in data transmission, modelling, digitized information, and reverse engineering to ensure quality assurance throughout the design process.

We offer our clients access to Finite Element Analysis and Moldflow Analysis images at the design stage, eradicating the need for costly revisions further on in the manufacturing process.

At HH Plastic Metal Co., we prioritise effective communication and collaboration throughout the design and manufacturing process. We achieve this through a direct network link, from our designers to our shop floor computers.

Here, our machine operators build bespoke machining programs for our clients. This efficient structure allows our teams to promote effective data transfer and ensure a cohesive and efficient service.

We are passionate about ensuring quality standards for our clients. By conforming to a rigid set of quality controls and investing in the latest machine tooling technology, we can ensure each finished tool precisely aligns with the specification, to high-quality standards.

This not only ensures the satisfaction of our customers, but also keeps costs low by minimising waste at the manufacturing stage.

Established in 2013, HH Plastic Metal Co. is based in the economic centre of Shenzhen, China. Our comprehensive services span from the initial design process, through to the manufacture and mass production of plastic injection mold design, precision tooling, parts, and associated fixtures.

Harnessing the advances in CAD and mold tooling technology, combined with our extensive experience in the industry, we create quality molding tools for our clients in the automotive sector. We have successfully developed many tools used to produce components for world-class automotive clients such as Peugeot, Mercedes Benz, Jaguar Land Rover, and Bentley.

We maintain a responsible controlled management theory, rigorous Quality Control, and a professional engineering team, enabling us to provide quality mold tooling and enhanced customer service to our clients.

We are proud to be fully registered under ISO 9001 regulations, specialising in the design and manufacture of high-quality molding tools.

Our mission is to provide high-quality tooling with meticulous attention to detail.

Plastic injection molding is an essential step in the manufacturing process for automotive parts.

This includes nearly every component in automotive design, from large body parts, such as bumpers and door panels, to intricate dashboard components and internal parts such as cylinder head covers, battery casings, and oil gauges.

Plastic Injection molding is imperative for ensuring the overall quality of your finished product. It ensures that each product created is consistently in line with your design specifications, to a high level of accuracy.

As a result, it guarantees that your finished vehicle does not only run flawlessly, but achieves high levels of customer satisfaction, supporting your brand to stay current in the modern automotive market.

Plastic injection molding in the automotive industry goes further than quality assurance; it is also essential for ensuring vehicle safety.

By improving the accuracy, durability and consistency of internal parts, plastic injection molding reduces the risk of malfunctions, helping to ensure the safety of your customers and the reputation of your brand.

At HH Plastic Metal Co., we have the capacity and the technology to manufacture the most minute of dashboard components, to large parts, with our biggest machine capable of handling tooling weighing up to 30 tonnes in weight.

Why Use Plastic Injection Molding For Automotive Tooling?

• Highly scalable

• Accurate components

• Enhanced color-matching capabilities

• Improved efficiency at the mass production stage

• Improved lifespan and durability of automotive parts

• Suitable for detailed designs and high-quality finishes

• Rapid tooling techniques ensure fast turnaround at the prototyping stage

Contact Us If You Need Top-Quality Automotive Industry Tooling!

- Highly scalable

- Accurate components

- Enhanced color-matching capabilities

- Improved efficiency at the mass production stage

- Improved lifespan and durability of automotive parts

- Suitable for detailed designs and high-quality finishes

- Rapid tooling techniques ensure fast turnaround at the prototyping stage