Checking Fixtures

Precision Automotive Checking Fixtures

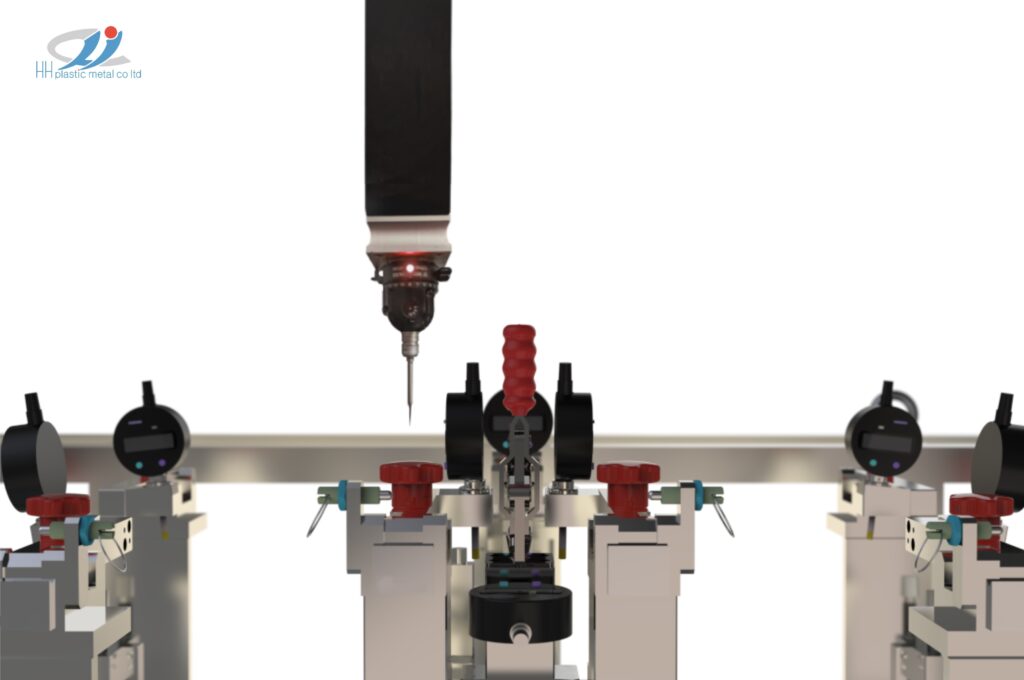

At HH Plastics Metal, we understand that accuracy and repeatability are critical in the automotive sector. That’s why we design and manufacture high-quality checking fixtures specifically tailored for plastic injection moulded components.

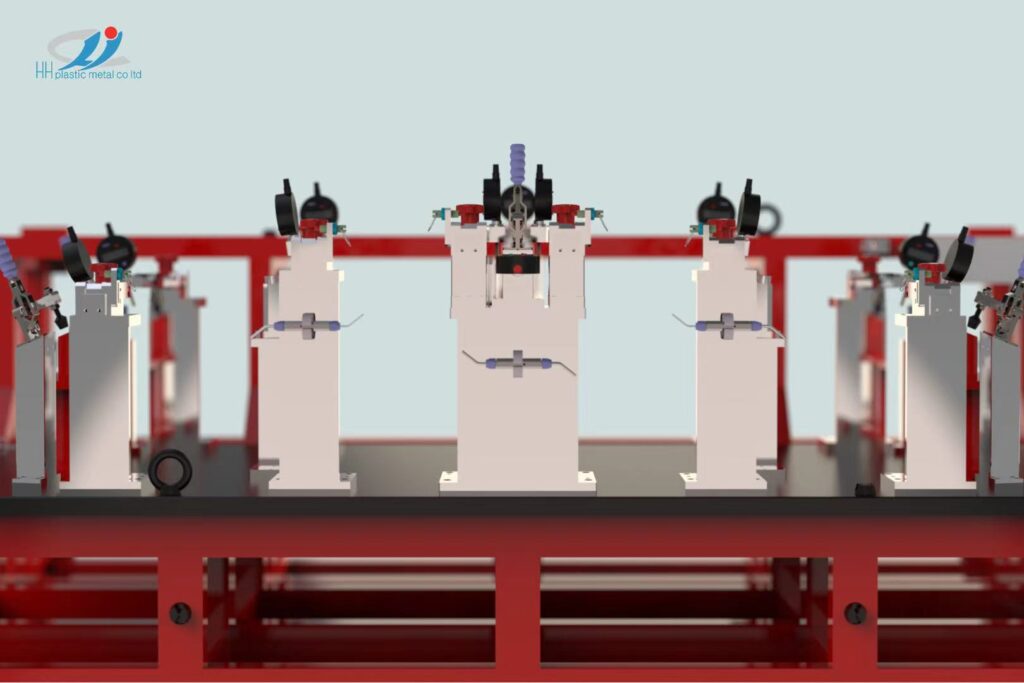

Our fixtures are engineered to ensure that every part produced meets strict automotive standards—helping our clients maintain quality, reduce waste, and improve production efficiency. Whether you’re working with complex interior trims, under-the-hood components, or exterior plastic parts, our fixtures provide fast, reliable measurement and verification.

Why Choose HH Plastics To Be Your Checking Fixture Manufacturers?

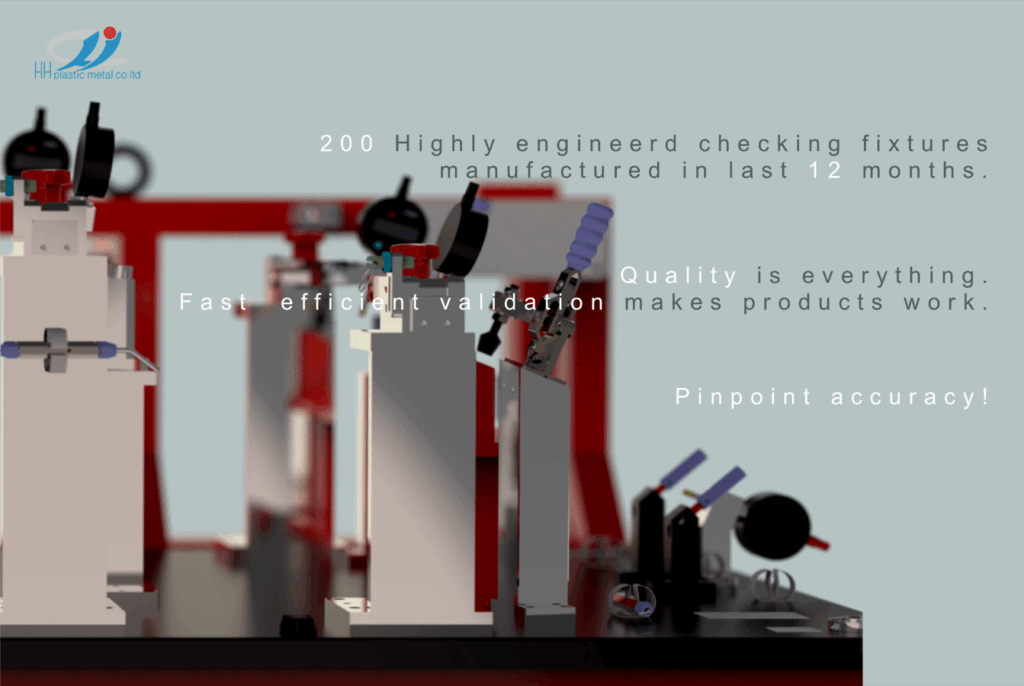

At HH Plastics, we’re proud to be a trusted partner in the automotive plastic injection moulding industry — and our high-precision checking fixtures play a key role in delivering the quality and consistency our clients rely on.

More than just an add-on, checking fixtures have become an integral part of our tooling solutions, enabling customers to ensure dimensional accuracy, improve quality control, and streamline production from day one.

Now, we’re taking things a step further.

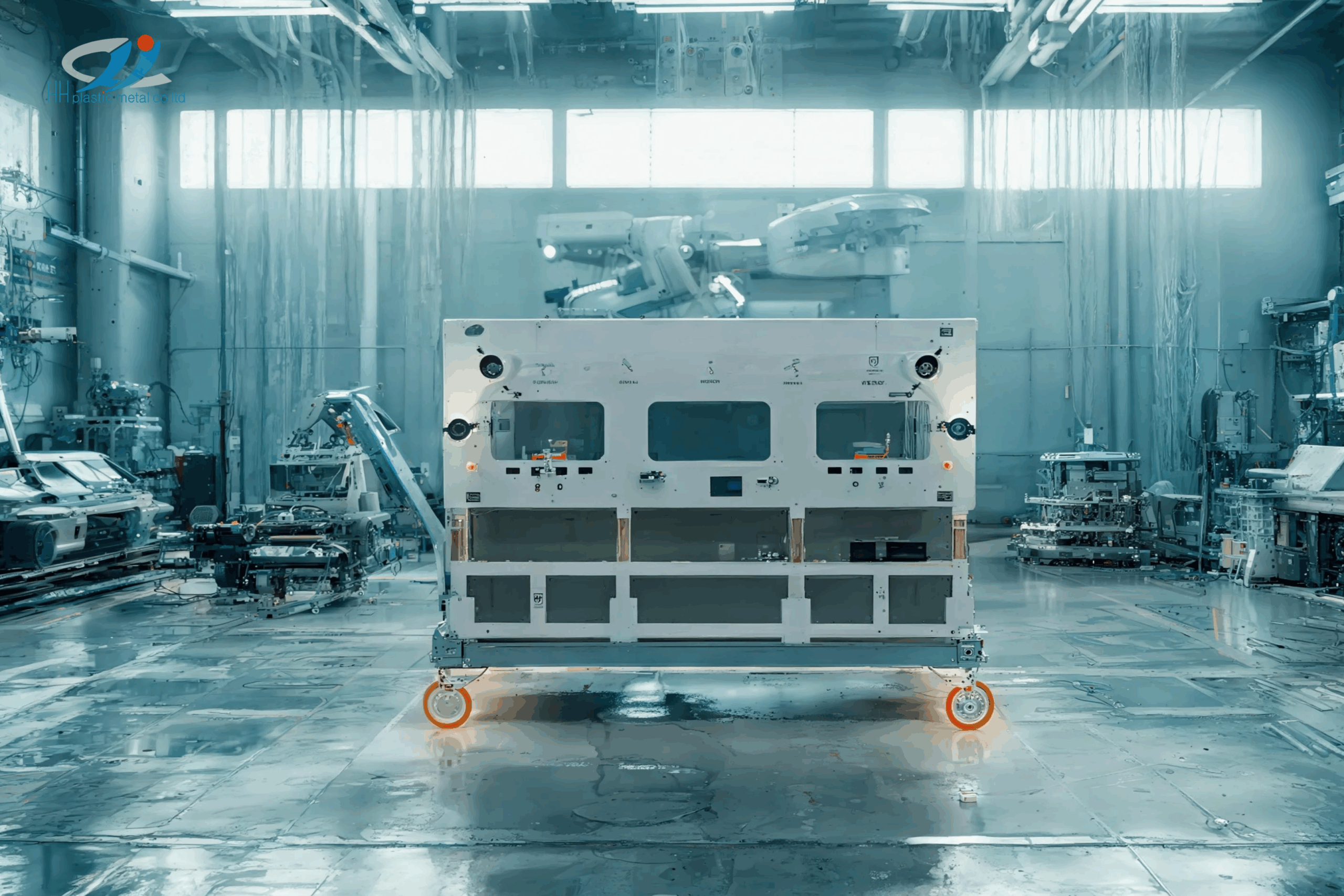

Expanding Our Capacity For Automotive Checking Fixtures

Recognising the growing demand for reliable, expertly built checking fixtures, we’re expanding this service to stand on its own — offering our expertise to a broader market, including OEMs and third-party toolmakers. Whether you’re looking to validate components, ensure compliance, or enhance your inspection processes, our checking fixtures are engineered for performance and built to last.

This strategic move is about more than growth — it’s about adding more value to the industry. By creating a dedicated business unit focused solely on checking fixtures, we’re strengthening our commitment to innovation, quality, and customer success.

With HH Plastics, you don’t just get fixtures — you get confidence, precision, and a partner focused on pushing boundaries.

Checking Fixtures Trusted By Automotive Suppliers Around The World

As part of our commitment to delivering excellence, we work closely with our customers to ensure every fixture not only meets technical requirements but also integrates seamlessly into their production workflow. Our checking fixtures are used daily on factory floors across the world and are trusted to help maintain the highest levels of quality.

If you’re looking to improve inspection efficiency, reduce downtime, and increase confidence in your output, talk to us about your next checking fixture requirement.

We collaborate closely with our clients from initial concept through to production to ensure every fixture supports their specific requirements, because precision matters.

Why Choose HH Plastics Metal for Checking Fixtures?

Tailored to Your Parts: Each fixture is custom-designed for your exact geometry and tolerances.

Automotive Expertise: Built to meet the demands of tier 1 and tier 2 automotive suppliers.

Durable & Accurate: Manufactured with robust materials and high-precision processes.

Support for PPAP & QA: Ideal for use in first-off inspection, PPAP submissions, and ongoing quality control.

Whether you require checking fixtures as part of a full tooling project or as a standalone solution, HH Plastics is ready to deliver with precision, speed, and industry insight.