Markets We Serve

Learn More About

The Markets We Serve

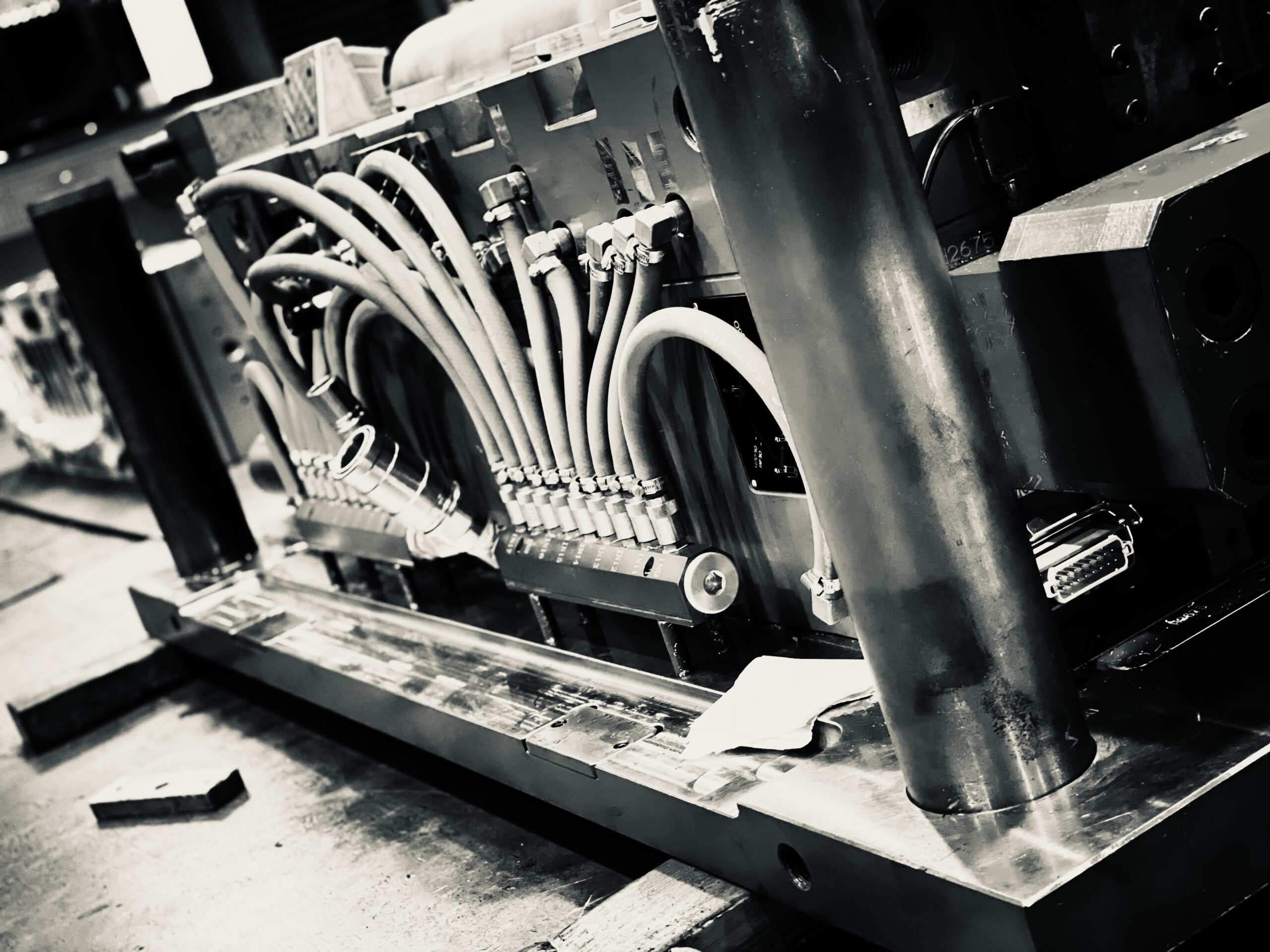

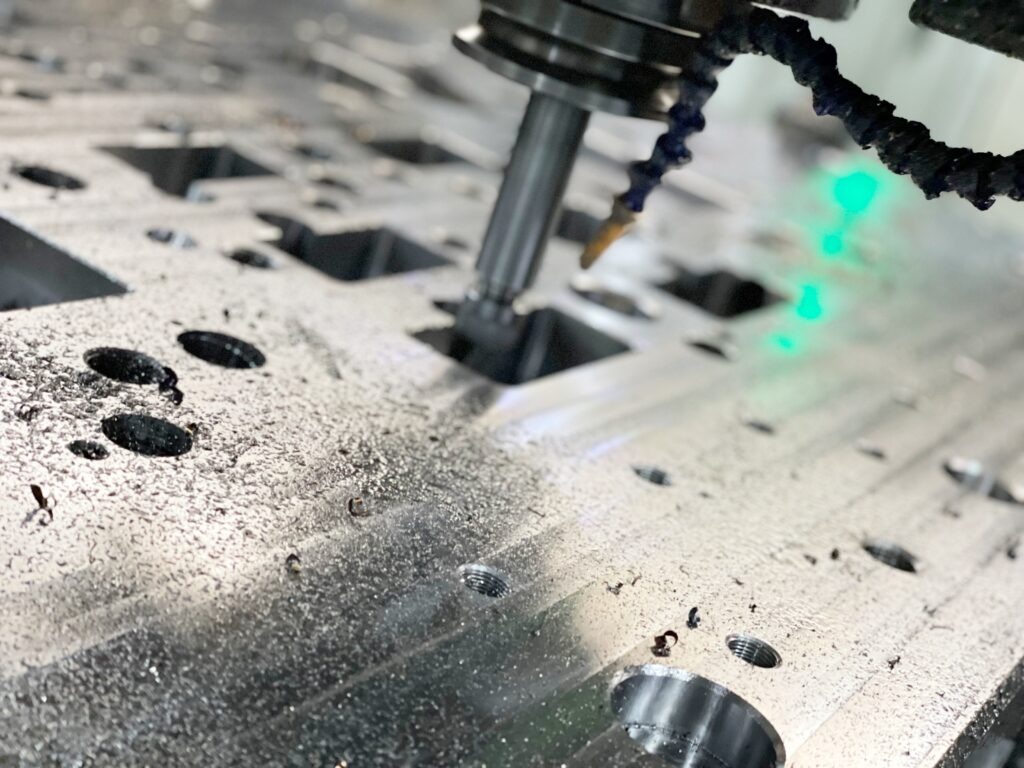

At HH Plastic Metal Co., Ltd, we are proud to provide high-quality, world-class Plastic Injection Mould Tooling, Tool Design, End of Arm Tooling, Gauges and Checking Fixtures to a diverse range of industries. Our expertise and advanced capabilities enable us to meet the stringent demands of each market, ensuring that our clients receive the best solutions tailored to their specific needs. Below is an overview of the key markets we serve and why these industries require top-tier injection mould tooling provided by HH Plastics:

Our mission is to provide high-quality tooling with meticulous attention to detail.

The automotive industry demands precision and reliability in every component to ensure the safety and performance of vehicles. Our injection mould tooling solutions are essential for producing intricate parts with tight tolerances, from engine components to interior fittings, to wheels arch liners and bumpers. High-quality tooling, including precision hot-runner technology, is critical in this industry to achieve consistency, durability, and compliance with stringent safety standards.

In the medical field, precision and sterility are paramount. Our injection mould tooling is used to manufacture a wide range of medical devices, including diagnostic equipment, surgical instruments, and disposable medical products. The high standards required in this industry necessitate tooling that guarantees accuracy, biocompatibility, and cleanliness, ensuring patient safety and product reliability.

The aerospace industry relies on components that must withstand extreme conditions and meet rigorous safety requirements. Our advanced tooling solutions enable the production of complex aerospace parts with high precision and excellent material properties. High-quality injection mould tooling is vital for this industry to ensure the performance, reliability, and safety of critical aerospace components.

In the construction industry, the demand for durable and robust components is ever-present. Our tooling capabilities facilitate the production of high-strength plastic parts used in building materials, infrastructure, and construction equipment. Precision and quality in tooling ensure that these components meet the necessary standards for structural integrity and long-term performance.

The consumer goods market requires versatile and innovative tooling solutions to produce a wide variety of products, from household items to electronics. Our injection mould tooling enables the efficient production of high-quality consumer goods with aesthetic appeal and functional excellence. Consistency, durability, and cost-effectiveness are key in this competitive market, making our superior tooling solutions indispensable.

The electronics industry demands components with high precision and intricate details. Our injection mould tooling supports the production of electronic housings, connectors, and other critical parts. Ensuring tight tolerances and high repeatability, our tooling solutions help deliver the reliability and performance essential for electronic devices

The packaging industry requires tooling solutions that can produce a variety of shapes and sizes with high efficiency. Our tooling enables the production of durable and aesthetically pleasing packaging solutions for food, beverages, pharmaceuticals, and more. High-quality tooling ensures that packaging is both functional and attractive, meeting consumer expectations and regulatory standards.