News

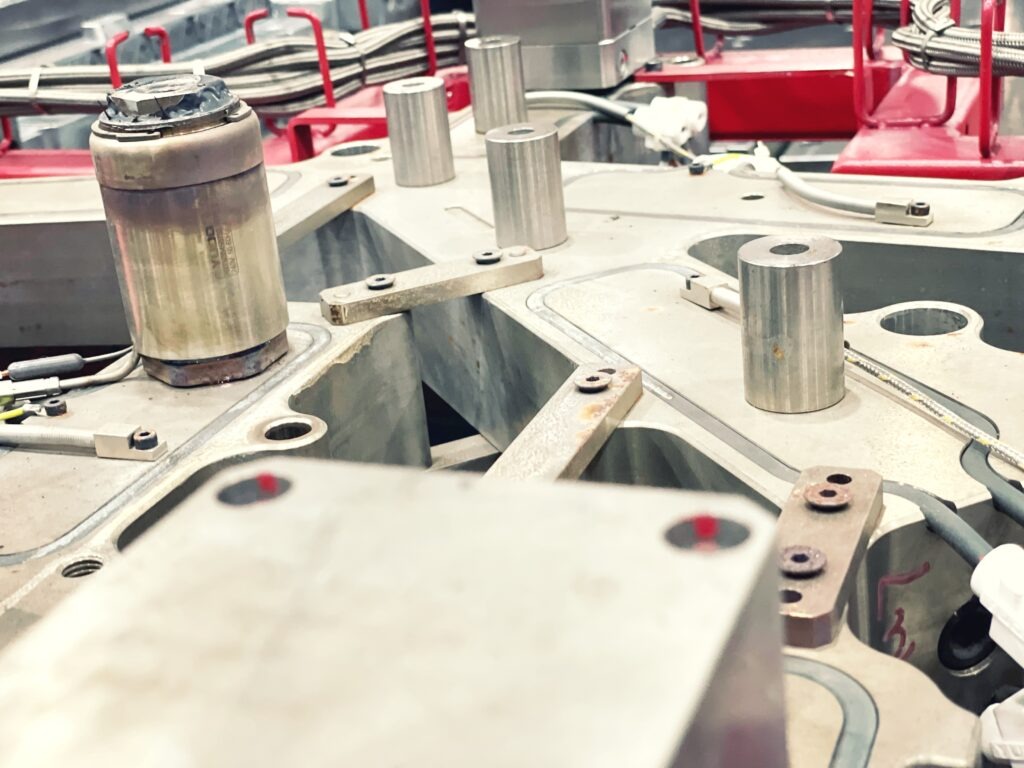

In the automotive sector, tooling is more than just a mould — it’s the foundation of precision, efficiency, and product quality. At HH Plastic Metal, we pride ourselves on delivering world-class injection mould tooling that combines the cost-efficiency of Far Eastern manufacturing with technical rigour and project management. Why Tooling Quality Defines Production Success Injection […]

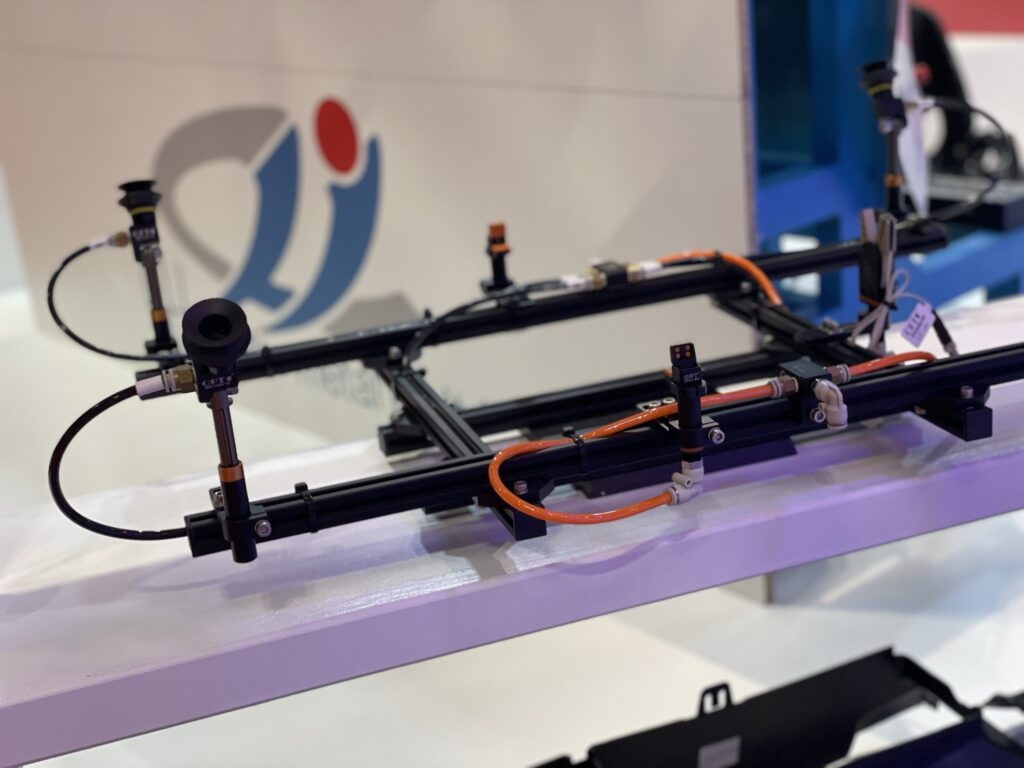

In high-volume automotive injection moulding, parts don’t just need to be moulded to spec — they must be handled, trimmed, and validated with precision before they ever reach final assembly. That’s where End of Arm Tooling (EOAT) plays a critical role. When EOAT is designed and manufactured by the same team that engineers the mould […]

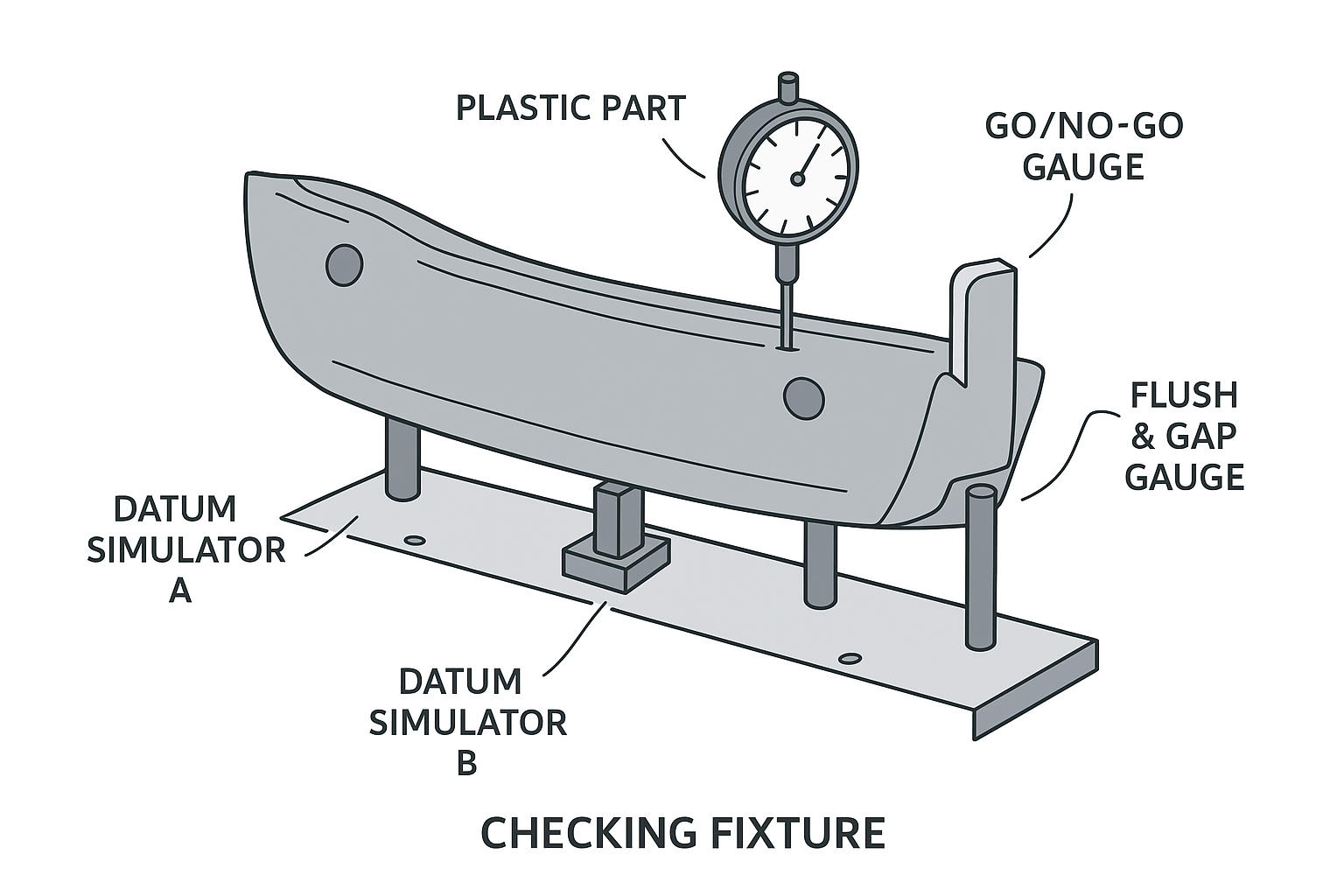

In automotive plastics, dimensional precision is directly tied to functionality, aesthetics, and assembly efficiency. With complex geometries, Class-A surfaces, and tight GD&T tolerances, we cannot rely on visual inspection or CMM audits alone. Checking fixtures provide a robust, repeatable solution for validating parts against design intent — directly on the shop floor. The Role […]

At HH Plastics, we are proud to deliver bespoke tooling solutions to clients across the globe. As part of our commitment to international growth and innovation, we are now extending our services into the thriving manufacturing sector in Mexico – a country with a fast-growing reputation for advanced automotive and industrial production. Bespoke Tooling – […]